Henan Doing Environmental Protection Technology Co., Ltd

Refine by

Families

28 products found

Henan Doing Environmental Protection Technology Co., Ltd products

DOING - Model 100 - Cost to set up a pyrolysis carbonization plant in India:

Total Cost Estimate Small - scale plant: With an annual processing capacity of less than tens of thousands of tons, the total investment cost may be between $100,000 and $500,000. Medium - scale plant: With an annual processing capacity of around tens of thousands of tons, the total investment cost may be between $1 million and $3 million. Large - scale plant: With an annual processing capacity of over hundreds of thousands of tons, the total investment cost may be between $10 million and tens of millions of dollars. Operational Costs Energy consumption: Pyrolysis requires high temperatures (400℃ - 800℃) and consumes significant energy like electricity and gas. Energy costs vary based on local energy prices and the factory's energy efficiency. They generally range from thousands to tens of thousands of dollars per month.Henan Doing - Model DY-T-1 - charcoal briquette making machine

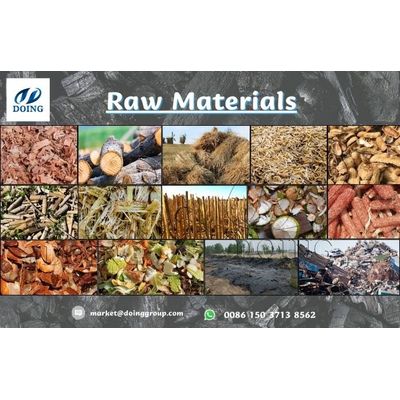

Regular maintenance is key to ensuring the longevity and consistent performance of your charcoal briquette machine. Common practices include daily cleaning of the mould and feeder, lubricating moving parts to reduce wear, and inspecting the hydraulic system for leaks or pressure loss. Operators should also adjust the machine according to raw material hardness and moisture content to avoid overload. Proactive upkeep not only prevents unexpected downtime but also maintains briquette density and shape uniformity.Henan-Doing - Model 500,1000 - High Efficiency Lithium Battery Recycling Machine - Automatic Li-ion Battery Crushing, Separation for Metal Recovery

Lithium battery recycling equipment is used for recycling and processing mobile phonelithium batteries, plastic shell batteries, soft lithium batteries, cylindrical lithium batteries.power lithium batteries, battery positive and negative electrode materials, etc. This machineadopts dry physical separation method to shred, crush, magnetically separate, screen, andgravity sort lithium batteries, separating copper, aluminum, black powder, iron, and plasticfrom waste lithium batteries. By using physical recycling methods to turn electronic wasteinto treasure, it not only reduces resource waste but also brings good economic benefits.Henan Doing - Model DY-500,1000 - Photovoltaic Panel Recycling Plant | Solar Cell Silicon Wafer & Aluminum Frame Recovery System with High Purity Rate

In South Africa, the proper disposal of waste solar panels involves recycling rather than landfilling. Specialized recycling equipment is used to safely dismantle panels, separate materials like aluminum, glass, silicon, and copper, and recover over 95% of their components for reuse.Henan-Doing - Model DY-T-1 - Industrial Biochar Pyrolysis Equipment | Automatic Carbonizer for Coconut Shell/Wood/Rice Husk to Bio-Charcoal Making

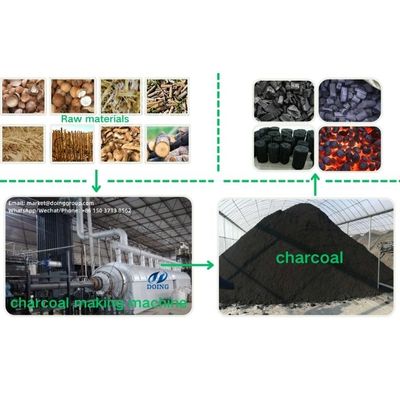

Coal and charcoal differ in origin, composition, and environmental effects. Coal is a fossil fuel mined from ancient geological formations, while charcoal is a renewable, man-made fuel produced from biomass using modern carbonization technology.Continuous Pyrolysis Plant

Henan-Doing - Continuous Process Manufacturing Pyrolysis Plant

Pyrolysis is a thermochemical decomposition of orgnic material at elevated temperatures in the absence of oxygen. Pyrolysis typically occurs under pressure and at the operating temperatures at 430℃. Pyrolysis is a special case of thermolysis, and is the most commonly used for organic materials, being, therefore, one of the processed involved in charring. In general, pyrolysis os organic substances produces gas and liquid products and leaves a solid residue richer in carbon content.