Industrial Heat Transfer, Inc. (IHT) products

Gas Turbine Inlet Air Processing

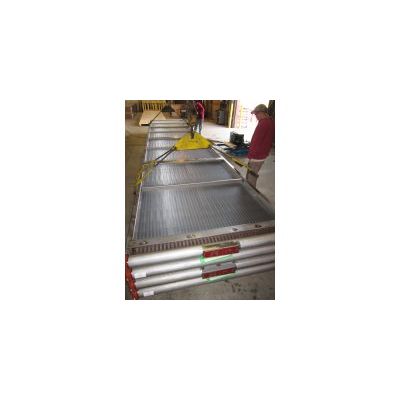

IHT - Gas Turbine Inlet Air Chilling Coils

At Industrial Heat Transfer, Inc., we design and manufacture chilling coils for a vast array of turbine applications. Our turbine inlet chilling coils are built for longevity and performance. Choose IHT coils to keep your turbine inlet cooling system operating at maximum efficiency for years to come.

IHT - Gas Turbine Inlet Air Heating Coil

The temperature of air entering in gas turbines used for power generation must be precisely controlled to optimize air conditions and meet performance targets.

Other Products

IHT - Industrial Heat Exchanger

Designed for simplicity, durability, and efficiency, air to water heat exchangers (or water to air heat exchangers) work by using water from a supplied source to either absorb process heat from, or supply process heat to an air stream. Because of their increased efficiency and relatively low energy consumption, air to water heat exchangers are highly sought-after for a number of industrial applications.

IHT - Air Compressor Intercoolers & Aftercoolers

Functioning to remove generated heat, air compressor intercoolers and aftercoolers are used in various applications, such as turbo charged and supercharged engines, air conditioners, refrigeration systems and more. These heat exchanger units work by cooling the intake air emerging from a compression unit to an ambient air temperature. Air compressor intercoolers and aftercoolers do the same thing, the only difference is that intercoolers cool air before it gets to the compressor, whereas aftercoolers cool air after it comes out of the compressor. Exceptionally efficient and quick, these units work exceptionally well for a variety of scenarios.

IHT - Motor and Generator Coolers

Overheated electric motors and generators can be inefficient, less effective and even dangerous when pushed to extremes. If you have a large generator or electric motor you know will be exposed to intense heat, Industrial Heat Transfer, Inc. offers both electric motor and electric generator coolers for your business’s unique application. Using either air cooled or hydrogen cooled designs, our systems help bring optimum efficiency, performance, and improved reliability for your electric motor application.

IHT - Steam Coils

A common method for heating large commercial and industrial spaces, steam coils work to heat a permeable grate of aluminum, copper, or stainless-steel fins though a series of horizontal steam coils. As the name suggests, the heat generated by these horizontal steam coils is generated through the condensing of steam, resulting in latent heat being released. This is an exceptionally efficient way of heating a space and is a popular option for large spaces with an exceptionally large heat load.

IHT - Waste Heat Recovery Heat Exchangers

Heat and energy waste are big factors in both the efficiency and environmental impact of a company’s operations. A waste heat recovery heat exchanger helps aid in the process of heat integration. These units reuse excess heat energy that would otherwise be disposed of or released into the atmosphere in the form of steam or smoke. By using a waste heat recovery heat exchanger, these industrial applications are able to reduce their energy use and costs, along with their CO2 emissions—all while improving their production efficiency and bottom line. Used across numerous industrial and commercial applications, the heat exchanger systems offered through Industrial Heat Transfer are designed for applications where a large volume of low-pressure gas is being handled by a round duct or pipe.

IHT - Air Cooled Heat Exchanger

Air Cooled Heat Exchangers, also known as Fin Fan Heat Exchangers, are one of the most common types of industrial heat exchangers on the market today due to their low maintenance and operating costs. These heat exchangers operate by passing air over a conductive fin surface and transferring heat to or from a fluid flowing through conductive tubing which has been mechanically bonded to the fins.

IHT - Heat Exchanger

Industrial Heat Transfer is an ASME certified shop. With our current U stamp, Um stamp, and R stamp capabilities we are able to design, manufacture, and repair ASME heat exchangers using state-of-the-art technology, and industry leading best practices. We take pride in our ability to consistently provide customers with high quality custom-designed industrial heat exchangers for industrial applications. With over 35 years of experience, we understand the uniqueness of your situation. Our custom ASME Heat Exchangers are designed and built to meet the specific needs and performance requirements of your specific application.