- Home

- Companies & Suppliers

- Downloads

Sekab products

Chemistry

Sekab - Model 64-17-5 - Ethanol

Sekab can help you meet your sustainability targets by offering bio-based chemicals for your processes. Our chemicals are identical and have the same quality as the fossil-based alternatives but are produced from bio-based raw materials in a process run on green bioenergy and can significantly reduce your environmental footprint.

Biorefinery Technology

CelluAPP - Biorefinery Technology

Carbon-neutral raw materials for new environmentally friendly chemicals, biofuels and energy carriers. The forestry and timber industries, agriculture, the food and manufacturing industries. Many companies have one thing in common – cellulose-based by-products, a resource they do not know how to make best use of. Sekab has developed CelluAPP® in response to this need.

Sekab - Cellulose Using Biorefinery Technology

Using our biorefinery technology we can decompose cellulose. Cellulose is a carbohydrate that forms the major part of all plants’ cell walls and is thus the most common organic substance in nature. Cellulose is relatively hard, making plants stiff and steady. The plant fibres consist almost entirely of cellulose and can be utilised by man in many ways. For example, the fibres of linen and cotton are made into thread and yarn, pulp and special viscose are made from wood fibres, and can then be converted into paper and textiles. However, we humans cannot use cellulose as food. Our stomachs cannot digest it. Nevertheless, a small amount of plant fibres is good to keep your stomach in shape. The animals that are best at making use of cellulose are the ruminants, for example cows.

Sekab - Cellulosic Sugar

Sugar from lignocellulose: Sekab’s CelluAPP technology comprises process technology for the production of sugar solutions from lignocellulose. Basically, the raw material is pretreated so that sugar is released and the crystalline structure of the cellulose is broken down. More sugar is released through enzymatic hydrolysis. Using our CelluAPP technology we can extract cellulose sugar. Cellulose sugar can be used in the production of many different types of biochemicals and biofuels.

Others

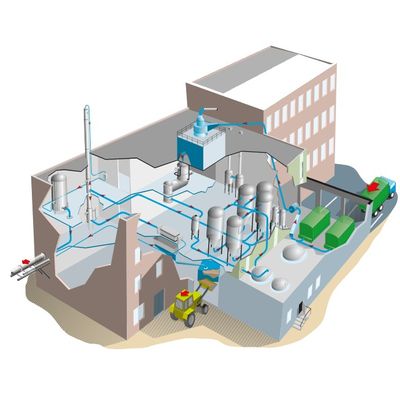

Chemical Plant

Circular production with bio based raw materials. In Sekab’s chemical plant, we produce acetaldehyde, ethyl acetate and acetic acid. We refine and convert ethanol into biofuels and ethanol-based chemical products. We work in catalytic processes in which the ethanol raw materials react highly effectively, the largest by-product being ordinary water.

Biorefinery Process Technology

This is how we can make sugar and ethanol from cellulose. The process developed by Sekab E-Technology consists mainly of four steps: pre-treatment, enzymatic hydrolysis, fermentation and reprocessing. When the raw material has come into the plant, it is transferred to a vessel where it is pre-treated with acid and steam at a temperature of 200 degrees. This releases sugars from the hemicellulose. The process converts the material into a porridge-like slurry. In the next step, the acid in the slurry is neutralised so that the environment is right for later reactions.