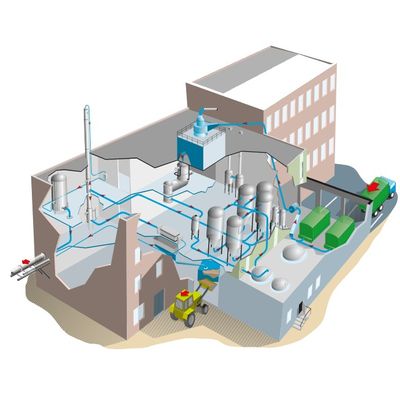

Biorefinery Process Technology

This is how we can make sugar and ethanol from cellulose. The process developed by Sekab E-Technology consists mainly of four steps: pre-treatment, enzymatic hydrolysis, fermentation and reprocessing. When the raw material has come into the plant, it is transferred to a vessel where it is pre-treated with acid and steam at a temperature of 200 degrees. This releases sugars from the hemicellulose. The process converts the material into a porridge-like slurry. In the next step, the acid in the slurry is neutralised so that the environment is right for later reactions.

The mixture is then transferred to another vessel and enzymes. The enzymes break down the cellulose into sugar. The sugar can be separated and used in other process solutions. If ethanol or any other chemical using yeast is to be produced, yeast and perhaps water are added. The yeasts ferment the sugar from both the hemicellulose and the cellulose into ethanol or other chemicals.

To access the ethanol, the entire slurry is distilled and the ethanol is taken care of, purified and dewatered. What remains in the slurry is mostly solid lignin which is filtered off and dried. The lignin can be used as biofuel or processed into other products.

In the remaining water there are residues in the form of solutes. These are broken down into biogas with the aid of bacteria. It can be used to supply the plant with energy or refined and sold on.