SparkNano products

Model Vellum Series - Market Leading Large Area Fab Solution for Flat Samples

Vellum is tailored designed for sheet to sheet (S2S) applications for deposition on substrates ranging from 0,5 x 0,5m up to 1 x 1.5 m. Substrates like metal or polymer foils, wafers, glass and porous substrates. All aimed at real production throughput up to 20 substrates per minute. In combination with a large variety of deposition materials and deposition temperatures. The substrate flow handling and inline integrated set-up of the system will be in designed as the overall set-up requires. The Vellum product line is a fully automatic processing platform for high throughput.

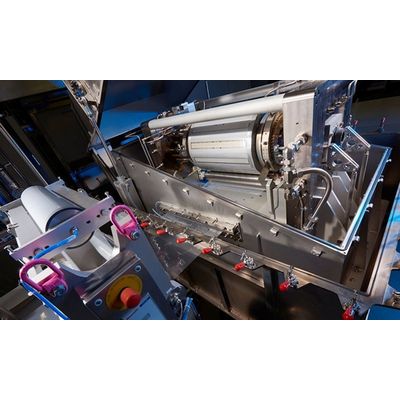

Model Omega Series - Proven Roll-To-Roll (R2R) System

Spatial Ald Technology

Labline Series

LabLine 6

Technical features: flat substrates like polymer and metal foils, wafers, glass and porous substrates. Substrate size: A free envelope of 175 mm x 215 mm x 5 mm is available. In this volume any flat substrate can be placed with a substrate specific holder. Process: Both thermal and plasma enhanced s-ALD

LabLine 12

Technical features: Substrate types flat substrates like polymer and metal foils, wafers, glass and porous substrates. Substrate size: A free envelope of 320 mm x 360 mm x 5 mm is available. In this volume any flat substrate can be placed with a substrate specific holder. Process: Both thermal and plasma enhanced s-ALD