Zhengzhou Boiler Co., Ltd. (ZBG) products

Industrial Gas & Oil Fired Boiler

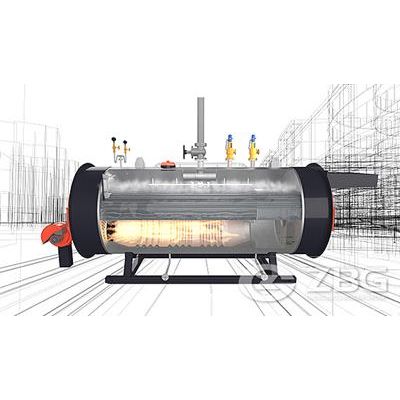

Model WNS - Fire Tube Boiler

As the subproject of high efficient and green boiler in the World Bank Group`s GEF Program, each technical index of WNS series oil and gas fired boiler has reached the world advanced level. WNS series boiler is fast-assembly installation boiler and it mainly consists of boiler proper, interconnecting flue, burner, steam&water system, meters, economizer and condenser (optional). It has the advantages such as clean combustion, no pollution in the emission, easy operation, high output and so on.

Biomass Fired Boiler

Model DZL - Packaged Biomass Steam Boiler

DZL packaged boiler can burn both coal and biomass fuel with a high efficiency. Compact structure and easy installation ensure efficient, clean, economic, safe and stable boiler operation, so it is widely used as an energy-saving and environment-friendly equipment in industry.

Chain Grate Boiler

Model SZL - Assembled Chain Grate Coal Fired Boiler

SZL series water-tube boilers utilize double-drum horizontal structure, composed of a main boiler frame, rear cast-iron fuel economizer, flues, auxiliary boiler, and pipeline valve instruments. The structure is compact, simple to install, ensuring boiler operation is highly efficient, clean, economical, safe, and stable, providing energy conserving and environmentally friendly thermal power equipment for ease of user production.

CFB Boiler

Model CFB - Power Plant Boiler

CFB Power Plant Boiler is a kind of large scale heating equipment applied in thermal power plant and other industries for power generation, it has the features of fuel flexibility, high combustion efficiency, low NOx, SOx emission, it is the good clean heating or power solution.

Waste Heat Boiler

Carbon Rotary Kiln Waste Heat Boiler

Our company’s carbon kiln waste heat boilers adopt vertical inverted II structure, furnace structure is novel with excellent performance. We mainly manufacture two series natural circulation water tube waste heat recovery boiler, i.e. carbon rotary kiln waste heat boiler and tank type carbon waste heat boiler.