Refine by

Pyrolysis And Why Is Pet Not Suitable For Pyrolysis Articles & Analysis: This-Year

26 news found

Pyrolysis oil, also known as bio-oil, is a product obtained from the pyrolysis process, which involves the thermal decomposition of organic materials such as waste plastics, tires or oil sludge in the absence of oxygen. Boasting a calorific value of 25 - 35 MJ/kg, pyrolysis oil surpasses common coal and wood fuels, making it a widely used alternative fuel for boilers and various industries. The ...

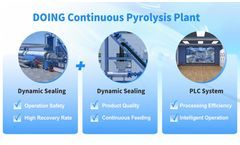

A continuous pyrolysis plant requires a coordinated system of equipment to achieve uninterrupted feeding, pyrolysis, product separation, and environmental protection. Here’s a detailed breakdown of the core components: 1. Raw Material Pretreatment System Shredder/Crusher: Reduces raw materials (e.g., waste tires, plastic, biomass) to uniform sizes (2-5cm) for efficient pyrolysis. Drying ...

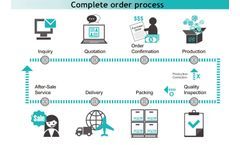

As a pyrolysis machine manufacturer, DOING Company is dedicated to delivering a smooth and efficient pyrolysis machine delivery process for our clients. Below is a detailed overview of the typical timeline from order confirmation to commissioning to help you gain a clear understanding of what to expect.Order Confirmation and ProductionAfter your order is confirmed, a 30% deposit is required to ...

Pyrolysis equipment plant stands as an environmentally friendly recycling solution for waste. It not only curbs the pollution arising from waste itself but also eliminates secondary pollution throughout the recycling process. Pyrolysis equipment plant is an eco - friendly recycling approach that transforms various types of waste into fuel energy. On one hand, it can handle large volumes of waste, ...

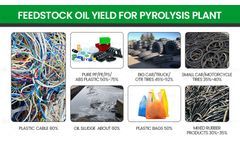

Several key factors significantly influence the oil output of a pyrolysis machine, which converts organic materials like plastic, rubber, or biomass into fuel oil through thermal decomposition.First, **feedstock properties** play a crucial role. The type of material matters: plastics with high hydrocarbon content (e.g., polyethylene) yield more oil than those with additives or lower purity. ...

Pyrolysis is a highly efficient method for recycling rubber products, especially those that are difficult to process using conventional mechanical recycling techniques. The method involves heating rubber in the absence of oxygen to break it down into valuable byproducts such as pyrolysis oil, carbon black, steel wire (in the case of tires), and non-condensable gases. Used Tires (Car, Truck, ...

Pyrolysis and combustion are both methods to process organic materials like waste tires, plastic, or sludge, but they differ drastically in environmental impact, resource recovery, and efficiency. Pyrolysis—defined as the thermal decomposition of materials in the absence of oxygen—offers distinct advantages over combustion (burning in oxygen), making it a preferred choice for ...

As a leading manufacturer of pyrolysis plants, DOING Company is dedicated to providing innovative and efficient solutions for waste-to-energy conversion. Our pyrolysis technology not only helps in managing waste but also produces valuable oil products that can be utilized in various industries.Understanding the Pyrolysis Process Pyrolysis is a thermal decomposition process that occurs in the ...

Is pyrolysis machine environmentally friendly? This is a question that many people ask when considering waste management solutions. The answer lies in the machine’s impact on the environment and whether it is equipped with advanced environmental configurations to reduce potential pollution. Henan DOING, a distinguished manufacturer of pyrolysis machines in China, offers a definitive ...

The cost of a plastic to fuel pyrolysis equipment largely depends on its model, processing capacity, the configuration, etc. Therefore, it is important to consider these factors comprehensively when choosing a suitable plastic fuel pyrolysis equipment. DOING has researched plastic to fuel pyrolysis equipments for 14+ years, and our plastic to fuel pyrolysis equipment can be roughly divided into ...

The start-up will use advanced technologies to process tyres in a sustainable way. Tyros, founded in May 2024, is investing in an electric pyrolysis reactor with the support of the Flemish government (1 million euros in strategic ecology support). This reactor will convert 9,125 tons of rubber granulate annually into valuable primary components such as recovered Carbon Black, pyrolysis oil and ...

Yes, plastic bags can be pyrolyzed. Pyrolysis is a thermal decomposition process that breaks down organic materials (like plastics) in the absence of oxygen, producing valuable byproducts such as pyrolysis oil, char (carbon residue), and gaseous hydrocarbons. Here’s a breakdown of the process and considerations: How Plastic Bag Pyrolysis Works Step 1: Feeding. The entire feeding process ...

Pyrolysis is an effective and sustainable method for converting waste materials into valuable products. These products, primarily pyrolysis oil, carbon black, and steel wire, have a wide range of applications across multiple industries, including energy, automotive, construction, and chemical manufacturing. This article delves into the applications of these pyrolysis products. Pyrolysis Oil ...

Through an advanced pyrolysis process, used tyres will be converted into tyre-derived oil, which will then be refined into Sustainable Aviation Fuel and road fuels. This initiative is poised to achieve over 80 per cent reduction in life cycle carbon emissions compared to traditional fossil fuels. Expected to begin operations in 2026, the Sunderland facility will reach full capacity by 2027, ...

Nowadays, where waste management and resource recovery are of paramount importance, pyrolysis machine have emerged as a promising solution. However, you cannot buy a pyrolysis machine blindly. Before you invest in a pyrolysis machine, here are five crucial questions to consider, along with insights into how DOING's machine stand out. What Types of Waste Can the Machine Process? Understanding ...

ARESOL is a business group that develops, executes, and operates renewable energy projects of all magnitude, from conception to installation and operation. Within the company’s expansion plan, Aresol intends to develop and implement several pyrolysis projects for end-of-use tyres in Spain, and for this reason, it chose the Canadian pyrolysis technology developed by Ecolomondo. Ecolomondo ...

In the realm of environmental recycling solutions, pyrolysis systems, also known as pyrolysis machines, plants, or equipment, have emerged as a crucial means to transform waste tires, plastics, oil sludge, and other discarded materials into valuable energy resources. As a trusted and seasoned manufacturer and supplier in the industry, Huayin takes pride in presenting a comprehensive lineup of ...

Heavy fuel oil is a type of petroleum - based fuel with specific characteristics and uses. Here is a detailed introduction: Definition and Composition of Heavy Fuel Oil Heavy fuel oil is a viscous, dark liquid fuel, which consists of complex hydrocarbon mixtures, mainly containing high - molecular - weight hydrocarbons such as paraffins, aromatics, and asphaltenes. Additionally, it may contain ...

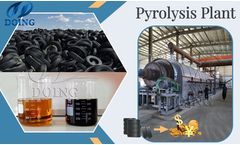

With the global increase in waste tire and plastic pollution, pyrolysis technology has emerged as an efficient and eco-friendly solution to recycle these materials into valuable products, especially fuel oil. A pyrolysis plant uses high-temperature, oxygen-free environments to break down tire rubber and plastic polymers into smaller molecules, resulting in the production of fuel oil, carbon ...

Celebrating Success! Huayin recently completed the installation of 10 sets of 15TPD (tons per day) waste tire pyrolysis machines for a valued client in China. This follows the customer’s prior order of 20 sets, reflecting their continued trust in our technology and satisfaction with the machines’ high productivity and operational efficiency.At Huayin, we combine reliable machine quality with ...