Refine by

Waste To Fuel Articles & Analysis

72 news found

Patrick shares the backstory of the birth of the American Biogas Council 15 years ago, the growth trajectory of the industry over the years, and the policy drivers that have helped the U.S. convert more of its organic waste to valuable fuel and electricity. The interview includes insight into the evolution of energy production from biogas and where the industry ...

Pyrolysis equipment plant stands as an environmentally friendly recycling solution for waste. It not only curbs the pollution arising from waste itself but also eliminates secondary pollution throughout the recycling process. Pyrolysis equipment plant is an eco - friendly recycling approach that transforms various types of waste into ...

As Congress prepares to deliberate critical clean energy tax provisions, the American Biogas Council (ABC) has launched an online advertising campaign to spotlight the power of biogas facilities to convert waste into fuel, electricity, and economic opportunity. The campaign, which began today in Washington, DC, and will air for the next two months as the debate ...

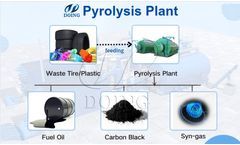

DOING design three types of pyrolysis machine: batch types, semi-continuous type and full-continuous type to recycle these wastes to fuels, Here is a detailed introduction: Process of DOING pyrolysis equipment Feeding: The waste is first sorted and pre - treated to remove non - combustible materials and reduce the size of the ...

Setting up a waste tire to fuel oil pyrolysis machine project involves several key steps to ensure its success, from initial planning to operational execution. ...

Thanks to the swift actions of the government and enterprises, an increasing amount of industrial waste is being recycled or converted into alternative fuel to generate electricity or heat. In Busan, a GD13Q twin-shaft shredder from GEP ECOTECH has been operating continuously for nearly five years, shredding, sorting, and recycling materials such as pulper ...

Henan DOING Company stands at the forefront of the waste to fuel recycling machine production field, renowned globally for over 14 years of expertise. ...

China-Henan DOING is a top-rated pyrolysis plant manufacturer in waste to fuel recycling machine production field. We are specialized in waste to energy field for more than 14+ years. ...

2 sets of 15Ton Daily Capacity Semi-continuous scrap #tire #plastic to oil #pyrolysis plant were delivered to #india from Henan DOING Company Higher automation degree than batch pyrolysis plant, favorable prices than fully continuous pyrolysis equipmentSemi continuous pyrolysis plant can continuously process raw materials such as waste plastic, tires, and oil sludge, generating ...

High environmental protection and profits DOING pyrolysis machine won't produce other pollution, such as our cooling system uses circulating water to avoid water pollution, waste gas control system to fully purify exhaust gas to avoid air pollution. In addition, the pyrolysis machine can recycle waste tire plastic to fuel oil, carbon black and ...

A fully continuous waste tire to fuel oil pyrolysis processing line is a system designed for the recycling of waste tires through a process called pyrolysis. ...

This includes automatic fire alarm systems, firefighting agents, fire monitoring equipment, and close collaboration with local fire departments. 5. Waste management: Properly handling and disposing of generated waste. Ensuring that waste meets emission and disposal standards prevents adverse environmental and health impacts. DOING pyrolysis ...

Pyrolysis plant will inevitably produce pollution during the waste to fuel production process. These pollutions are mainly flue gas pollution from flue gas emissions, tail gas pollution from non-condensable gases, and dust pollution from carbon black collection. ...

The continuous pyrolysis plant ordered by the Chinese customer can recycle waste tire plastic to fuel oil and carbon black, which can help the Chinese customer generate huge profits with their multiple uses: 1. Fuel oil 1) The fuel oil can be used in cement factories, steel factories, generators and boiler heating. 2) The ...

Our regular Canadian customer once purchased a set of 10TPD oil sludge pyrolysis machine to recycle waste oil sludge to fuel oil, which was delivered to Canada in February, 2023. ...

Waste tire to oil process is a pyrolysis process, and the whole process needs high temperature.Here is the detailed introduction of DOING pyrolysis machine working process: 1. Put the waste tires into the reactor. 2. Heat the reactor by using fuel materials, such as coal, charcoal, fuel gas, wood etc. ...

The skid-mounted pyrolysis plant ordered by the Kazakhstan customer is the batch type, which can recycle about 100KG waste plastics or waste tires per batch. With the pyrolysis machine, we can recycle waste plastics to good quality fuel oil, carbon black and combustible gas; and if we recycle waste tires, we can ...

Energy Information Administration (EIA) announced that, in 2019, renewable energy consumption levels in the United States increased for the fourth year in a row, reaching a record 11 percent of total energy consumption. Wood and waste energy, wood pellets, and biomass waste from landfills accounted for approximately 24 percent of U.S. renewable energy use. ...

This short article on pyrolysis of waste tyre to fuel oil?takes a good look at the whole process of converting your typical waste into something useful. ...

The continuous pyrolysis plant helps owners create value out from all of this waste by converting it into fuel oil and carbon black. This plant uses the pyrolysis process to break down existing chemical bonds using heat, while facilitating the formation of new ones. ...