- Home

- Companies

- SynTech Bioenergy, LLC.

- Products

- CPC BioMax - Model 100 Gen2 - Advanced ...

CPC BioMax - Model 100 Gen2 - Advanced Modular CHP Gasification System

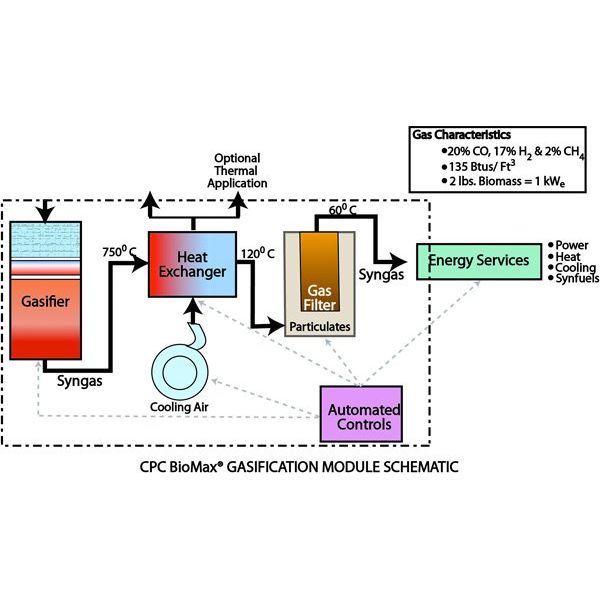

The world`s most advanced modular CHP gasification system. 145 kWe net. Commercially ready. Field proven. Uses no water and produces no waste water. Meets US EPA standards. Fully automated. Remote monitor and control. Operates 24x7. CPC`s BioMax® Gasification Systems convert carbon-rich, biomass feedstocks into a clean producer gas (syngas) containing equal amounts of hydrogen and carbon monoxide, a small amount of methane, some carbon dioxide, water vapor and the balance nitrogen. CPC`s proprietary gasification technology enables the producer gas stream from the BioMax® to have extremely low level of tar, such that the systems use no water for gas clean up and produces no waste water that requires treatment before disposal, unlike most gasification systems.

The BioMax® systems are fully automated, using software to precisely control material flow, gasification, gas cooling and filtration to produce extremely clean syngas. The systems can also be monitored and controlled remotely. The high degree of automation and remote monitoring capability enables the BioMax® to be able to operate unattended. Unlike thermal energy derived from incineration of organic feedstocks, the BioMax® Systems’ syngas is a clean burning renewable fuel gas that can be used as a substitute for gasoline, natural gas, fuel oil or propane. Using gas-to-liquid Fischer Tropsch technologies, the BioMax® Systems’ syngas can be further processed into a number of chemical products including synthetic diesel, jet fuel and more. In the near future, customers will be able to produce liquid fuel (syndiesel) by adding our liquid fuels module (LiquiMax®).

- BioMax can be configured for numerous energy services including combined heat and power (CHP), gas only (boilers & driers), and cooling.

- BioMax is a turnkey system. It is built in ISO 20ft containers and tested in factory, and can be installed in under a week. The customer need only provide a concrete pad, electrical and thermal (if desired) inter-connects.

- BioMax can operate 24x7, with or without sunlight, with or without wind.

- BioMax uses highly efficient and advanced proprietary design, down-draft gasifier technology that produces extremely low level of tar in the producer gas.

- BioMax employs dry filter for gas clean-up. It uses no water or oil scrubbers, produces no waste water (disposal issue); no water ponds required; no waste water treatment system (additional cost) required.

- BioMax100 is commercially available, proven, with multiple field installations.

- BioMax is fully automated, can be remotely controlled, can operate unattended. System start up, operation, monitoring, diagnosis and shut down can all be carried out onsite or remotely over the Internet using an iPad, iPhone, PC or similar devices. Important system functions are continuously monitored and logged with three levels of alarms (alerts are sent via the Internet to a smart device or computer). Emergency or scheduled shut downs are automatic and do not require an on-site attendant.

- BioMax requires low maintenance. Maintenance and Operation BioMax systems require approximately 30-45 minutes per day for maintenance and to prepare the biomass feedstock.

- BioMax meets US EPA requirements.

- BioMax enables biomass ‘waste’ stream mitigation to reduce or eliminate disposal cost.

- BioMax produces usable biochar byproduct.

- BioMax has a compact footprint – 30ft x 30ft (10m x 10m), unlike most renewable energy systems of similar power output.

The BioMax system delivers on its promises.

The customer benefits include:

- Cost savings (power, heat, cooling and waste reduction)

- Energy independence & security

- 24 x 7 energy production

- Easy to install and easy to move

- Environmentally friendly

Typical BioMax User Benefits:

- Converts onsite or nearby waste streams and/or residues to energy services (power, heat, cooling)

- Reduces dependence on fossil fuels and the electric grid

- Locked-in energy savings – eliminate utility and energy services price increases

- Adapts to feedstock changes that may occur in the customer’s business

- The BioMax® system applications can be added or removed to accommodate changing customer business equipment and practices

- Reduced emissions and other environmental concerns enhancing a company’s image

Community Power Corporation (CPC) has developed a number of modular BioMax® system technologies and products that convert a variety of biomass feedstocks into power, heat and/or cooling.

CPC’s automated, modular biopower products include the core BioMax® Gas Production Module that converts a wide variety of woody biomass into clean, environmentally friendly and versatile nitrogen-diluted syngas. The syngas can displace various fossil fuels by powering spark or compression ignition engine generators, or the syngas can be combusted in conventional boilers, dryers or similar equipment.

The BioMax® Gas Production Module is a highly versatile platform that can integrate with a number of gas-based energy application modules to provide electricity, heat and/or cooling. The BioMax® is designed much like a battery pack tool that integrates with a drill, saw, sander, etc., providing the flexibility needed for end-use applications. Similarly, the BioMax® Gas Production Module can accept three different front-end feedstock conditioning modules:

- Ready-to-use, such as nutshells, pellets, etc.

- Wood chips

- Processed feedstock such as briquettes, etc.

The primary function of the BioMax® system is to convert the photosynthetic energy stored in biomass materials (organic materials) into a clean synthetic fuel gas (~17% hydrogen, 20% carbon monoxide, 8% carbon dioxide, 2% methane and the balance nitrogen) that can be converted by engines, generators and downstream chemical processors into electricity, heat and/or cooling.

The photosynthetic energy stored in the biomass feedstock is converted to other forms of energy by means of a thermochemical reaction in a proprietary computer-controlled downdraft gasifier. The gasifier is the heart of the BioMax® System.

The gasification process is fully automated via a proprietary control algorithm and a highly sophisticated control system that has been developed and refined through thousands of hours of operations in the field.

The BioMax® system uses a shell and tube heat exchanger to cool the gas stream in the BioMax® Gas Production Module. Waste heat from the gas cooling is used to dry feedstock. The BioMax® system does not use any form of liquid cooling or scrubbing of the gas, eliminating the need for any water. The char/ash particles are removed by self-cleaning, passive bag-type filters and automatically stored in collection bags. Depending on the feedstock, the recovered char/ash can be used as a soil amendment.

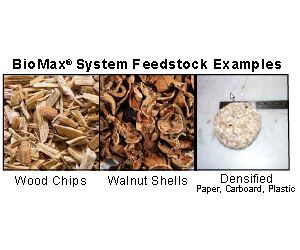

To date, the BioMax® has converted over 40 different feedstocks including: wood chips, wood pellets, nut shells (coconut, walnut, almond, nutmeg), orange skins, grape skins, Timothy hay, Army wet and dry packaging and feeding kitchen waste, cardboard, and plastic utensils among others. While this demonstrates the flexibility of the BioMax®, the front-end processing module and control program are always selected to meet the end-user’s feedstock requirements.

The standard 20‘ ISO containers (modules) for a BioMax® System typically include:

- Feedstock processing and feeding (optional, the feedstock may or may not require sorting & drying)

- Gas generation and cooling

- Gas filtering

- Power generation (optional)

The advantages of the modular BioMax® System include:

- Stabilized future energy costs.

- Higher availability than solar and wind (sun and wind not needed; 80+% availability).

- The modules can be integrated into a larger kW to MW configurations.

- Standard 20’ ISO containers can be shipped to virtually any site and easily moved with a standard forklift truck or crane.

- Sub-systems and components are easily accessed in each module.

- The ISO containers protect the equipment from weather and other exposures.

- The BioMax® generates minimal noise during operation.

- Factory assembly of modules reduces field installation time.

- Electronic control architecture includes remote operation.

The BioMax® Systems’ stacked container arrangement is unique and makes for a smaller footprint with a high power density, easy installation, and fewer conveyances for the feedstock.

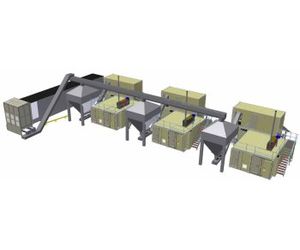

The below illustration of a BioMax Energy Farm™ installed at Premier Mushrooms, Colusa, California shows how BioMax® Systems can be grouped into larger energy plants of multi-kW to mulit-MW capacity.

The Premier Mushroom installation consists of three (3) BioMax®100 Systems. The three systems typically operate in tandem, but have been deliberately configured to function as independent individual systems that send electric and thermal energy to a central interconnection point at the customer`s site.

The flexibility of the BioMax® Systems` configuration makes it practical to site large energy farm installations on a foot print that is approximately 10% of a similar sized solar energy installation.

The advanced electronics of the BioMax® System allow individual modules in the energy farm to be controlled by a centralized control system making it easy for an operator to coordinate the operation and to maximize energy production.

End-user designed and built custom feedstock delivery systems can be intregated into the BioMax Energy Farm™ further increasing flexibility of the installation and expanding the type of feedstocks that can be used for energy production.

Additional options available for the BioMax Energy Farm™ further increase value for the end user. These include:

- Advanced Heat Capture System

- Backup Power Systems

- Future Air Conditioning/Refrigeration Systems

- Maintenance and Support Programs

- Onsite and at CPC Operator Training Programs

CPC, headquartered in Englewood, Colorado, is the world’s leading small modular biopower corporation.

CPC was founded in 1995 and started work in modular biopower in 1999. CPC’s was the first company world-wide to:

- Deploy automated, modular biopower systems capable of operating unattended in Energy Services Company (ESCO) applications.

- Manufacture complete, turn key modular biopower systems in standard ISO containers.

- Develop on-site energy independence solutions that can produce power, heat and cooling.

- Develop a modular syndiesel plant.

Is The BioMax® Affordable For You?

Unlike many other renewable energy systems, the BioMax® system produces power, heat and cooling and reduces waste disposal costs making it easy to confirm your cost savings.

The requirements for owning a BioMax® system are typically fairly modest:

- A desire to reduce operating costs

- Power, heat and/or cooling needs 24 hours per day

- Available space of 30’x30’

- Available feedstock of about 3.3 dry tons per day

Is A BioMax® In Your Future?

Community Power Corporation will help you analyze the savings you can capture and will provide you with the additional information needed for a purchase or lease decision.

Please have available or include in your email as much of the following information as practical, so your analysis can be completed quickly and accurately.

- Current electric cost, peak power demand and kWh/day usage

- Current natural gas, propane, fuel oil or similar cost and average monthly consumption

- Type of equipment used to produce and distribute heat and required BTUs per hour

- Type of cooling and refrigeration equipment used (building space cooling and/or walk-in box or refrigerated case applications)

- Type and quantity of feedstock available

Consumer Characteristics That Increase BioMax® Affordability

- High cost energy location

- Low cost or onsite feedstock (gasifiable residues)

- High waste disposal cost of onsite or nearby gasifiable residues

- Ability to use all power and heat or cooling produced

- 145 kWe net (standard power block is 145 kWe; can be banked together for larger applications)

- Fewer Modules (less setup time and cost)

- Advanced Operating System Automation

- Modular, Transportable, Flexible

- Small Footprint (30 ft. x 30 ft.)

- Makes No Water; Uses No Water

- Processes Wide Variety of Feedstocks: (wood chips, nut shells, stone fruit seeds, more)

- Integrated Interconnection Equipment

- Low Maintenance Requirements

- Clean & Green (meeting EPA requirements)

- Produces Electricity and Heat

- Reduces Power, Heat, Cooling Costs

- Stabilizes Future Energy Costs

- Higher Availability Than Solar and Wind (Sun and Wind Not Needed; 80+% Availability)

- Factory Built and Tested

- Utility Compliant

- Converts On-Site or Nearby Waste to Energy

- Supports Net Zero Energy & Waste Goals

- Creates Jobs - Helps The Local Economy

- Easy, Low Cost Installation

- 145 kWe net Modular Systems (sea level)

- Electricity: 3,480 kWh per 24 hours

- Heat: ~400,000 Btu/hour (CHP)(option for additional heat)

- Converts 2.0 lbs. feedstock/kWh(~3.5 dry tons/day)

- Syngas: ~ H2-17%, CO-20%, CH4-2%, CO2-8%, N2

- Foot Print: 30 ft x 30 ft.

- Complies With Utility Interconnection Requirements

- ~80% Availability (30 days between scheduled maintenance)

- Modules: Gas Production & Cooling, Gas Filtering,Power Generation & CHP, Feedstock Conditioning & Feeding (not all modules are required for all applications)