- Home

- Companies

- EBERL Trocknungsanlagen GmbH

- Products

- EBERL - Air Classic Drying Container ...

EBERL - Air Classic Drying Container Kilns for Efficient Wood Drying

EBERL's Air Classic Drying Container Kilns are designed to deliver efficient drying processes while maintaining a budget-friendly approach. These kilns employ insulated containers, available in sizes ranging from 6 to 18 meters, to meet diverse client needs. Constructed with high-quality stainless steel or aluminum interiors, the kilns ensure robust insulation. The system's core consists of components like fans, heaters, a spraying unit, and exhaust management. The drying is controlled precisely using a sophisticated control unit that adapts to various wood types and moisture preferences. Air distribution is managed by laterally mounted fans that work with electric or hot water heaters, while a counterflow heat exchanger can be added to optimize energy efficiency. User interaction is streamlined through an intuitive touch panel interface and optional remote control via smartphone, making real-time monitoring and adjustments simple.The compact and newly overhauled or completely new insulated containers are outstandingly suitable for being used as drying kilns. The inside walls are made of stainless steel or aluminium and they as well as the robust base have good insulation properties. In the factory, they will be equipped with high-quality components like fans, heaters, spraying unit, exhaust fan and inlet flaps as well as climate- and wood moisture content measurement.

The control unit, the drying schedules and our experience as kiln producer make the simple containers excellent but low-budget drying kilns which we perfectly adapt to customer requirements.

- Uniform drying

- Cost-saving and economic

- Easy installation

- Very good insulation

- Easy control

- Solutions adapted to customer requirements

- Front- and track loading

After loading the wood by means of track car, the drying process can be started. Laterally mounted fans press the air through hot water heaters or electruc heaters and evenly distribute the air over the entire kiln length. The drying climate can be exactly controlled due to air exchange by exhaust fan and air inlet flaps.

A counterflow heat exchanger can be used as an option. The fresh incoming air is heated quite effectively by the warm and humid exhaust air. This conventional drying kilns are characterised by fastness, equability and economy.

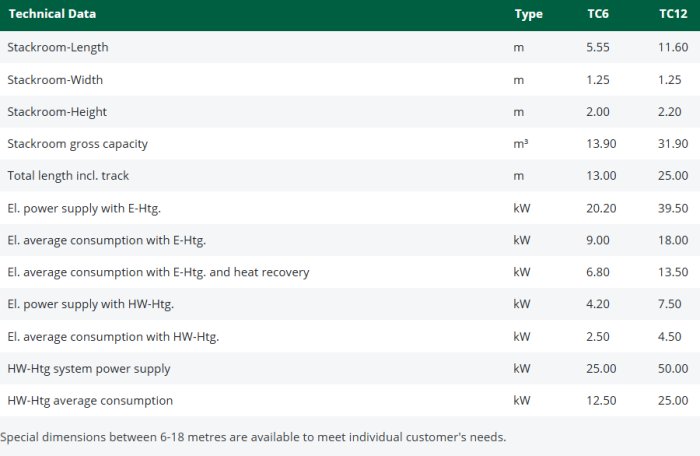

Standard sizes are:

- 6m container 6.1m x 2.4m x 2.6m (LxWxH)

- 12m container 12.2m x 2.4m x 2.9m (LxWxH)

- Special dimensions are possible at any time.