- Home

- Companies

- Ash Grove, a CRH Company

- Products

- Cadence Chem-Fuel - Cement Kilns for ...

Cadence Chem-Fuel - Cement Kilns for Energy Recovery

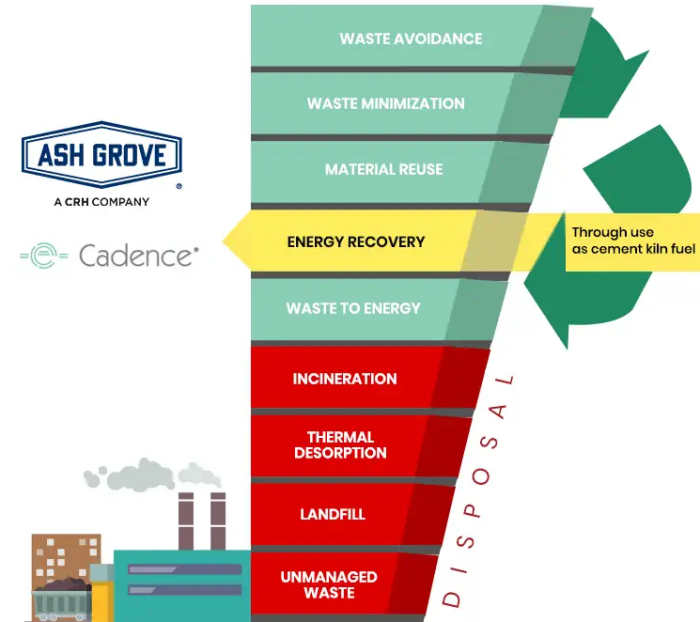

Cement Kilns are the ONLY thermal treatment option that uses all the waste as energy becoming a part of the final clinker product. This means no residual ash. No longterm liabilities having your waste in landfills. In 1975 Cadence was the first to use carbon-rich waste as fuel in cement kilns. Today, this fuel called Chem-Fuel® has helped industries large and small manage their hazardous wastes in the most cost-effective and environmentally responsible way possible. Since Chem-Fuel® replaces coal and other fossil fuels, these non-renewable resources can stay in the ground.Chem-Fuel is good for the industry and good the environment.

Cement Kilns are the only thermal treatment process that combine high temperatures and long residence times to insure complete destruction of wastes

REDUCED LIABILITY

Using wastes as alternative fuels in cement kilns is the EPA’s highest rated and approved technology for energy bearing wastes. Cement kilns have the highest waste destruction rates at above 99.999%. Wastes are destroyed most effectively in cement kilns because they are exposed to temperatures above 2600°F and with long residence times. This combination means all the waste is used as energy and there is no waste left as residual ash being sent to landfill. Cement kilns are the preferred thermal treatment process for recovering energy from carbon rich industrial wastes.

WASTE AS ENERGY

We do more than dispose of your waste. We put it to work as energy to make cement. Cadence developed the use of Chem-Fuel® using industrial wastes to replace the use of non-renewable resources as fuels for use in cement kilns. We’ve been identifying carbon-rich wastes to use in our Chem-Fuel° program since 1975. We now supply almost 200,000 tons of coal replacement fuels annually to the cement industry with primary supply to Ash Grove Cement.

COST-EFFECTIVE DISPOSAL

Ash Grove and Cadence have more than 35 years’ experience working exclusively together and constantly developing our hazardous waste-derived fuel operations. The two fully-permitted RCRA Part B hazardous waste combustors are centrally located in Foreman, Arkansas and Chanute, Kansas. Using wastes as fuels is good for our environment and makes the US cement manufacturers more competitive by reducing their operational cost. Our joint experience, plant locations, and technology makes us the most efficient and lowest cost option to our customers.

CONSERVE RESOURCES

Your waste will NOT be wasted. Our sustainable practices uses the carbon content in waste to replace non-renewable fossil fuels. One ton of waste on average replaces one ton of coal used to heat the kiln. Cadences aids in the conservation of 125,000 tons of coal annually. Together both Cadence and Ash Grove Cement have reduced coal usage by over 3 million tons since 1986 when we began working together.

INDUSTRY LEADER

Cadence has 45 years of waste-derived fuels experience. We were the first to use liquid industrial waste in cement kilns as an alternative energy source. Our leadership pioneered the use of alternative fuels and has been involved in developing this industry since the 1960s. Since exclusively joining forces with Ash Grove Cement in 1986, Cadence is and has been the exclusive supplier of hazardous waste derived fuels to Ash Grove Cement since 1986.

CADENCE CHEM-FUEL® PROOCESSORS

Nearby and ready to serve your needs

Chem-Fuel® cement kiln energy recovery permanently removes your generated waste from the environment while conserving coal and helping to make the world`s most important building product … cement.

We like to say...

"When your waste is used as Chem-Fuel® it`s GONE FOR GOOD!"