- Home

- Companies

- GreenPower

- Products

- GreenPower EKKO - Charcoal Furnace

GreenPower EKKO - Charcoal Furnace

Environmentally friendly furnace for carbonization of raw materials, including: energy and plantation wood and wood waste, fuel-briquettes (Pini-kay, nestro, ruv, etc.) and plantation wastes to produce high-grade charcoal. The main process used in the furnace is carbonization or low speed pyrolysis of plant materials containing carbon. In addition to the production of charcoal, heat energy is generated in the process. Extra heat can be used for preliminary drying of the raw material or for other purposes. If the customer wishes, it is possible to produce liquid pyrolysis products. Charcoal is widely used in almost all spheres of the global economy (see more details on the use of charcoal). Production of environmentally friendly high quality charcoal is an urgent problem in the development of the world economy.

Charcoal is widely used in almost all spheres of the global economy (see more details on the use of charcoal). Production of environmentally friendly high quality charcoal is an urgent problem in the development of the world economy.

Based on more 20 years of experience (since 2001, see the history of GreenPower), a unique safe pyrolysis unit has been developed, taking into account the basic requirements of modern consumers:

- The chamber of carbonization furnace is manufactured using modern insulating materials that can withstand ultra-high temperatures (up to 1300 ° C), which eliminates the need for “ballast” firebricks, concrete and sheet metal. This solution speeds up the process and increases plant efficiency.

- The automated control system developed by us allows automating the technological process and minimizing the influence of the human factor on the productivity of the charcoal furnace and the quality of the finished charcoal. The introduction of the ability to save all datas about production parameters at all stages of charcoal production in the Cloud storage via the Internet allows you to provide remote ONLINE control of the work of maintenance personnel and the entire technological process as a whole.

- The unique design, produced with experience out over 20 years, guarantees the reliability and maintainability of the charcoal furnace and it’s elements. The charcoal furnace will reliably serve for more than 5 years, if necessary, any part and element can be easily and quickly repaired or replaced.

- Logistics and mechanization. Competent and well-thought-out logistics of the charcoal production complex makes it possible to eliminate costs that may exceed the cost of the equipment itself: the purchase of expensive forklifts and the installation of hoists, crane beams, building of hard surfaces for production, which is necessary when using forklift. This compares favorably with most manufacturers, who usually do not indicate these costs, at the stage of purchasing charcoal furnaces.

- High quality at a highly reasonable price;

- Compactness and low weight (savings on delivery);

- Economical, no additional fuel is required, only to start the furnace;

- Low consumption of electrical energy < 0,1 kWh;

- Environmental safety – no harmful emissions during the operation of the furnace;

- Quick start of the furnace to the operating mode < 1 hour;

- Resistance of the combustion device to thermal shock;

- Quick first start of the new furnace, preparation < 8 hours;

- Possibility of transporting two to three furnaces in a container/truck;

- Charcoal retains the shape of the raw material, the fines fraction (undersize particle) of charcoal does not exceed 1%;

- High performance of the furnace, with relatively small dimensions

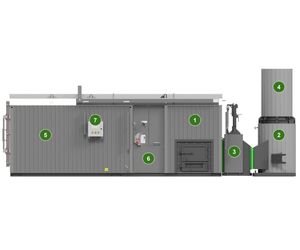

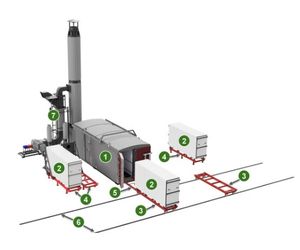

- Carbonization furnace

- Trolley

- Mobile platform

- Stationary trestle

- Portable trestle

- Rails for the mobile platform

- Preliminary dryer

For raw materials and finished charcoal trolleys are provided. Number of trolleys depends on the model, furnace configuration and operating conditions: the climatic conditions of the region, the size and moisture content of the raw materials. All actions to move the trolleys are performed using an electric winch.

There are two types of trolleys of raw material loading and charcoal unloading – with side or top loading /unloading. For mechanizing the processes loading and unloading of trolleys are using top type of trolleys. For raw material loading and for cooling charcoal are using stationary platforms for trolley. It is also possible to use a conveyor for loading raw materials into trolleys and a tipper for unloading charcoal from them. In this case, trolleys with top loading of raw materials will be the most suitable option.

The main factors affecting the productivity of the carbonization furnace are the moisture content and size of the raw material. To optimally prepare the raw material and achieve maximum efficiency, it is desirable to equip the furnace with additional equipment for preliminary drying. It can be the following units:

- Drying chamber of periodic action

- Preliminary dryer for the charcoal kilns

Chamber drying is more efficient than preliminary drying directly in the trolleys of raw materials. The efficiency of drying in the chamber is achieved due to the minimum heat loss from the process. For hot regions, of course, you can get by with pre-drying the raw materials directly in the trolleys.

The recommended degree of drying is less than 20% moisture content. A more efficient drying process brings double benefits:

- economic – significantly reducing the duration of processing, growth of the monthly/yearly production capacity;

- consumer and commercial – increasing the quality and yield of the final product.

Preliminary drying system for EKKO takes place outside of the furnace, which can significantly shorten the cycle time and increase the productivity of the furnace from 50 to 100% when using “fresh” wood. Read more about equipment for drying process by GreenPower.

Thanks to the introduction of the latest technologies, a wide range of raw materials can be subjected to environmentally friendly pyrolysis (more about the “pyrolysis” process):

- firewood, energy wood, lumpy wood materials, fuel waste;

- woodworking / logging waste, substandard timber (including roots, branches, etc.);

- various fuel briquettes (Pini-Kay, Ruff, Nestro, Nielsen)

The EKKO charcoal furnace is produced in one modification EKKO-2. The EKKO-2 model consists of 2 carbonization chambers. We use a couple of chambers, since carbonation takes place in two different reactions: endothermic and exothermic. Therefore, we use an exothermic reaction in one chamber to carry out an endothermic reaction in another. It should be noted that in charcoal production, the endothermic reaction can occur twice: in the raw material drying stage and primary pyrolysis, as well as in the charcoal calcination stage, if a high carbon content is required. The main advantages of EKKO furnaces are the ability to carry out the entire carbonization process without additional fuel or contamination.

The construction of the carbonization furnace consists of two process chambers, which are connected with: firebox; control chamber; afterburner for eco friendly process; chimney.

The logistics elements of production area are also provided, which include: trolleys for raw materials / charcoal; mobile platforms for moving of trolleys around the charcoal production complex; stationary platforms where charcoal cooling and loading of raw materials may take place; tipper of trolleys for unloading charcoal from trolleys.

Process chambers operate in “DRYING” or “PYROLYSIS” modes: a “RELOADING” mode is also provided.

The automatic control system ( ACS ) determines the mode in the chamber “DRYING” / “PYROLYSIS” / “PYROLYSIS END” / “CHARCOAL READY“. In addition, the ACS distributes the heat formed as a result of the combustion of pyrolysis gas released during the active phase of the PYROLYSIS process into other chambers that are in the passive phase of the process (drying or calcination of charcoal), this provides safety at all stages of the process. The automatic control system manages and monitors all the actions of the furnace, it also fixes all parameters, keeps logs of “temperatures and events”, personnel actions, etc. This makes it possible to comprehensively analyze and control equipment operation

- Firebox

- Afterburner

- Channel “connection of the firebox and afterburner”

- Chimney

- Pyrolysis chambers “A” and “B”

- Control chamber

- Control panel