- Home

- Companies

- Beston Group Co., Ltd.

- Products

- Beston - Model BST-J - Continuous ...

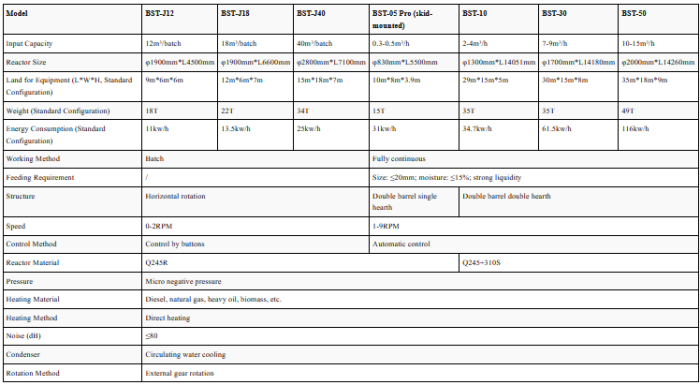

Beston - Model BST-J -Continuous Charcoal Making Machine

Continuous charcoal making machine can be used to convert biomass into biomass charcoal/biochar continuously for 24 hours. Besides, it can treat waste such as sludge in a harmless method. This equipment is welcomed by customers in the environmental protection industry because of multiple uses, large capacity and high automation level. Beston machines have been updated to the latest generation. They have advanced technology and high efficiency. If customers are interested in this equipment, please contact Beston. Beston provides customers with a series of services such as suitable machines, documents, technical support, installation, and after-sales services.

Why is Charcoal More and More Widely Used?

Charcoal has a wide range of applications, such as alternative fuels, soil remediation, composting, and more. Charcoal is a very popular alternative fuel and soil remediation/composting ingredient. Biomass charcoal has the following properties.

- Replace the use of some traditional fuels;

- Fix carbon in soil;

- It has higher combustion efficiency than firewood and coal;

- Balance soil pH and increase crop yield;

- Improve soil drainage and aeration;

- Absorb extra moisture in the soil;

- Remove various organic residues and heavy metals in the soil;

- It is smokeless and odorless when burning. It emits fewer greenhouse gases than firewood when burned;

- Charcoal has light weight. It is easy to store, transport and use. It has a wide range of applicatio

How to Make Charcoal Continuously in An Environmental-friendly Way?

Customers need to choose an appropriate machine to make charcoal. If customers use Beton equipment to produce biochar, the whole process is pollution-free and safe. When customers use continuous type, the process has high automation and high efficiency. The specific production process is as follows.

- Continuous models have requirements for the size and moisture of raw materials. The size is less than 20mm. Make sure that the raw material meets the requirements of the feeding material. Transport the raw materials that meet the requirements to the main carbonization furnace in a fully sealed method by automatic screw feeder. Heat the main furnace.

- After about 15-20 minutes, the material is carbonized into biochar. Biomass charcoal will be discharged by water-cooling discharging system. When discharged from the water-cooling system, the temperature of the biochar is about 30 degrees.

- The bio-gas in the main furnace can be directly used as heating fuel for the main furnace after being treated by the cyclone deduster;

- The hot smoke in the main furnace can be recycled and sent to the dryer. Hot air can be used to dry raw materials;

- The exhaust gas in the main furnace is treated by the condenser and the de-dusting tower and then discharged up to the standard, which meets the EU emission standard. If the customer has higher requirements on the exhaust gas, you can contact Beston. Beston can provide customized de-dusting system.

What Can Continuous Biomass Carbonization Machine Bring to Customers?

- When a customer chooses equipment, the customer needs to figure out whether the machine meets the customer’s needs. Beston carbonization equipment has a variety of applications. It can bring financial or environmental benefits to customers and governments.

- Make Money Charcoalhas a wide application market in many countries, like cooking, BBQ, shisha, alternative fuel. It is also one of the hot selling products for export. Customers can get rich profits from selling biochar. At the same time, it promotes the development of local upstream and downstream industries. And it is helpful to increase the local employeement.

- As an Alternative fuel for factories Some customers have their own factories. They use biochar as an alternative fuel for factories. In the long run, this project helps customers reduce part of their fuel costs.

- Soil Improvement/Compost Some customers use this machine to make biochar that is used in soil/compost. So that the plant will grow better.

- Government-funded ProjectGovernment-funded environmental programs recycle forestry/agricultural/organic waste. This project is an environmental protection project to reduce environmental pollution. Some governments give high subsidies when the client/government invests in the project.

- Increase Carbon Credits When a customer converts biomass to biochar, the customer adds carbon credits. Customers can use carbon credits (carbon offsets) themselves. Customers can also sell carbon credits for a profit.

It has screw automatic feeder, automatic water-cooling discharger (safe and clean). And this type works for 24 hours continuously. This will help customers to save labor and running cost.

This type has feeding capacity of 2-15m³/h. If the customer runs this equipment continuously for 3-5 days, then this biochar machine can help the customer process a lot of raw materials.

This design not only improves the carbonation environment, but also helps customers save part of the fuel cost. First, the outer cylinder is used for drying to improve thermal efficiency. Second, the inner cylinder can achieve material drying.

The on-site workshop is clean. At the same time, it is equipped with three layer of de-dusting system with ceramic ring absorption to achieve environmental protection standard operation. So, working environment is good for workers’ health.