Resynergi - Continuous Microwave Assisted Pyrolysis (CMAP) System

At the core of Resynergi’s technology is its patented Continuous Microwave Assisted Pyrolysis (CMAP) reactor, which processes 1.25 tons of solid plastic waste per day and rapidly converts it into a gas for downstream processing. What sets the CMAP apart from standard pyrolysis systems is its efficiency, reliability, and footprint owing in large part to the use of microwave temperature control.

- In the U.S., only 5-6% of plastic is ever recycled.

- Because of contamination and material degradation, conventional recycling efforts often fall short when faced with common plastics like HDPE, LDPE, PP, and PS.

- Our energy-efficient process converts non-ideal plastic waste into high-quality materials used to produce new circular plastics, keeping plastics out of our oceans and landfills.

A Revolution in Recycling

Our team of researchers and industry experts have developed the Continuous Microwave-Assisted Pyrolysis (CMAP) reactor, kicking off a revolution in recycling.

Using microwave energy, plastic molecules are broken down 100X faster than in traditional pyrolysis reactors.

Resynergi’s modular design allows for rapid deployment and scalability, making advanced recycling more affordable and versatile.

The energy-efficient process generates clean products with 68%+ lower carbon intensity than industry-standard methods.

Traditional pyrolysis systems depend on inefficient heating methods to control reaction temperature, which influences product yields and reaction rate. Waste plastics can contain many contaminants that affect the heating and breakdown process, making it difficult to produce a consistent and clean product from a variable waste stream. The CMAP reactor applies heat more thoroughly and with more control into the plastic, converting the material in 1/100th of the time of standard reactors.

The high processing rate of the CMAP system and the fine-tuning of the process offered by microwave heating means the system can be rapidly started or stopped by the automated control system.

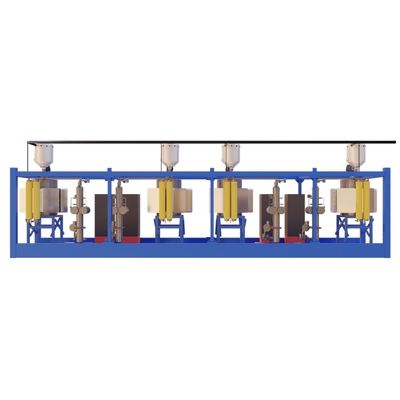

With the efficiencies offered by microwave heating, four CMAP reactors easily fit into a single 40ft x 8ft shipping container skid. The Resynergi 5T module, our advanced recycling “building block”, is made up of four CMAP reactors working independently to process a total of five tons of plastic waste every day, 24/7. These modules are easily paired up, eliminating the need for costly and slow scale-up operations. The small footprint and rapid scalability of Resynergi’s 5T modules mean plastic doesn’t have to be transported long distances for processing.