- Home

- Companies

- Acme Engineering Prod. Ltd.

- Products

- ACME - Model OH Series - Electric ...

ACME - Model OH Series -Electric Thermal Oil Heaters

Electric Oil Heaters represent a major advancement in oil heating technology, combining superior oil heating performance with the benefits of safe, clean, quiet, and efficient electric heating. Oil heaters were developed in 1965 specifically for the food processing industry and have proven exceptionally effective and reliable. All Acme Thermal Oil Heaters are custom designed and built to meet application specifications.

- Capacity: Up to 2000KW

- Voltage: Up to 600 V 3 PH. 50/60 Hz.

- Temperature: Up to 700ºF (371ºC).

- Pressure: Atmospheric to 20 bar.

- Maximum oil temperature without cooking or burning; minimizes oil carryout on the product without damaging the oil.

- Flameless design eliminates combustion hazards, emissions, and noise.

- No boiler or high-pressure steam; reduced operating and maintenance costs.

- Minimal maintenance required, resulting in less downtime.

- Located at the point of use; shorter runs and no special room required.

- Minimum flow restrictions, lower pressure drops.

- Uniform flow, no dead spots to overheat.

- Heating element and surface temperature matched to oil temperature.

- Low operating pressure despite the high temperatures.

- Close temperature control for accurate response.

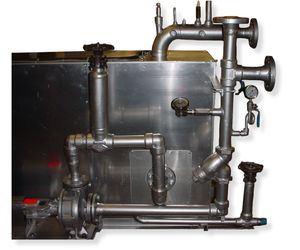

The oil to be heated is circulated through heat exchanger shells into which the flanged heating elements have been inserted. Internal baffles assure good flow across the heater elements which are assembled with individual replaceable blades.

Heating elements of the electric Oil Heaters are fabricated from tubing materials especially selected to provide the necessary electrical resistance and rated to keep the surface temperature low in order to prevent “cooking” or burning of the oil. Shell sizing and baffles are also calculated to minimize the hydraulic resistance to oil flow in order to keep the load imposed on a customer’s oil circulation pump as low as possible.

Acme Electric Oil Heaters, consisting of exchangers, oil supply and return headers and control panel are assembled and mounted on skid bases and housed in thermally insulated sheet metal enclosures.

The Acme Electric Oil Heater is equiped with a power regulator which proportions the electrical power input to the oil heater elements in response to a temperature controller which monitors the outlet oil temperature. Power may be disconected automatically either by the oil temperature limit controls or by the control system.

Oil temperature controls are mounted in a separate temperature control panel which is located near the heater. The temperature controller utilizes a thermocouple to sense the leaving oil temperature and provides a proportional signal to the power regulaor. Oil temperature hi-limit controls are provided in each exchanger to shut off the heater supply should the oil temperature rise above the set point.

Temperature control system provides regulation of electrical input over the full range of heater capacity.

- Steel shell(s), registered pressure vessel.

- 76 mm(3") insulation with painted steel jacket

- Support skid

- Individually replaceable Incoloy or steel heating elements.

- HRC fuses

- Contactors

- Control transformer, fused

- On-off switch

- Low level cutoff

- Electronic sequencer

- Hight temperature limit in each shell

- Pressure gauge

- Relief valve

- Temperature controller

- Temperature indicator

- Terminals for KW demand controller

- Manual control switches for each heating stage

- Pilot lights, one per stage

- Demand controller

- Dual oil/electric controls (bi-energy)

- Progressive sequence controller

- Unfused disconnect switch or breaker

- Door key lock

- Voltmeter with phase selector switch

- Audible and visual alarm circuit

- Ground fault trip and breaker

- Circulation pump c/w starter and fuse,

- prepiped and prewired

- Expansion tank