- Home

- Companies

- Energy Systems & Design (ES&D)

- Products

- ESD - X-Stream Engine

ESD - X-Stream Engine

New! Injection Molded housing with drip lip! In the 1970’s Paul Cunningham, owner and operator of Energy Systems & Design, had a need to power his off-grid house. He set off on a mission to create an efficient and reliable micro hydro machine. Utilizing a car alternator type micro hydro machine and the wheels he cast himself, he created the first machine. Through many hard-working days and design changes he was able to produce very efficient pelton and turgo wheels and sold these wheels to other enthusiasts.

After years of consistently improving the design he was able to create a highly efficient machine that was producing increased levels of power. It had become obvious that anyone with a suitable water source could be producing their very own renewable energy. With this idea in mind Paul established Energy Systems & Design in 1980.

- High Efficiency - resulting in more power from the water source

- Tunable Generator which maximizes output

- More user friendly - Easy to install and service

- Outputs of 2+Kilowatts (KW) and 12, 24, & 48 volt options. Generating 240 volts

- Operating Range from 3 meters (10ft) to over 100 meters (300ft)

- Can operate with 1 to 4 nozzles

- Employs a brushless, permanent magnet alternator

- Adjustable to match turbine output to electrical load

- Capable of outputs up to 2+ kilowatt (KW)

- Plastic and stainless steel turbine wheel options

- Universal nozzles or brass nozzle inserts

- Made of non-corrosive alloys for long life and durability

- Made in-house to ensure top level of quality control

- 1 Nozzle X-SE Plastic Turgo: $3150

- 2 Nozzle X-SE Plastic Turgo: $3240

- 4 Nozzle X-SE Plastic Turgo: $3420

- Stainless Steel Low Flow Option: $600

- Stainless Steel Turgo Option: $600

- High Voltage Option: $400

- High Current Option: $300

- Turbine Housing (Unmachined) DIY special: $100

- Turbine Housing (1 Nozzle) NEW: $200

- Turbine Housing (2 Nozzle) INJECTION: $225

- Turbine Housing (4 Nozzle) MOLDED: $275

- Universal Nozzle: $25

- Adaptor for Low Flow Nozzle Inserts NEW Black (1/2″ NPT): $25

- Adaptor for Low Flow Nozzle Inserts ABS (7/8-14): $30

- Nozzle Inserts (1/8,3/16,1/4,5/16,3/8,7/16,1/2) 1/2″ NPT: $25

- Stainless Turgo Wheel (Stream Engine Wheel): $750

- Stainless Turgo Wheel (Stream Engine Wheel) with Hub: $800

- Stainless Stream Engine Low Flow Wheel: $600

- Stainless Stream Engine Low Flow Wheel with Hub: $650

- Plastic Turgo Wheel: $350

- Plastic Turgo Wheel with Hub: $400

- Stainless Hub for Wheels (5/8-18): $80

- Bearing Kit, 3 x #6203 (Stream Engine & LH1000): $35

- Bearing Kit, Stainless Steel 2 x #6203 (Easy Tune): $35

- Rotor, Shaft and Hub Assembly: $450

- Rectifier: $35

- Junction Box: $300

Shipping Not Included. Pre-Payment Required On All Orders.

There are two basic modelswhich fit two different needs. The stream engine is designed to take advantage of sites with higher head while the LH1000 is designed for sites with low head and high flow. Both models are designed for battery-based power systems, with electricity generated at a steady rate and stored in batteries for later use. When AC power is desired an inverter is used to convert the stored energy. In grid tie applications, the machines are usually used to generate high voltage DC that is compatible with grid tie inverters. Our machines can also feed the utility grid.

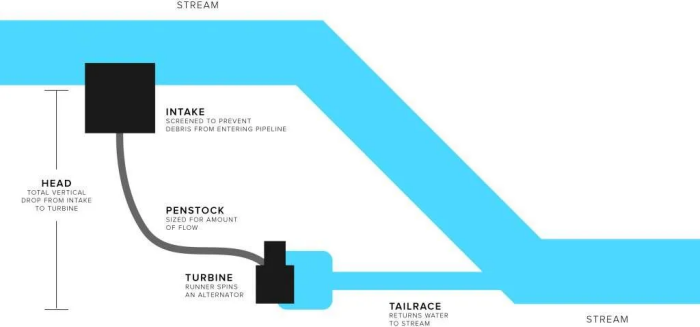

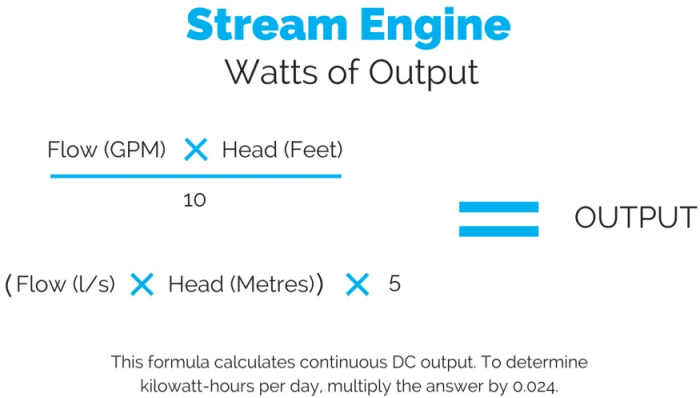

Our machines are designed to make use of a natural source of running water. Water from the stream is channelled into a pipeline to gain enough head (vertical drop the water falls) to power the system. The water passes through a nozzle, where it accelerates, strikes the turbine wheel and turns the generator shaft. The amount of power produced will depend on the head and flow from the water source.

Technical jargon broken down to help you understand how it all works.

Total Vertical drop of the water source from intake to turbine.

The vertical drop of the water source is greater than 3 meters or 10 feet

The vertical drop of the water source is between 1 meter or 3 feet and 3 meters or 10 feet

The Head Water is the source of the stream leading to the generator.

The tail water is the water that leaves the generator and is returned to the stream