EWK Umwelttechnik GmbH

- Home

- Companies

- EWK Umwelttechnik GmbH

- Products

- EWK - Model KAT - Catalytic Gas ...

EWK - Model KAT -Catalytic Gas Cleaning

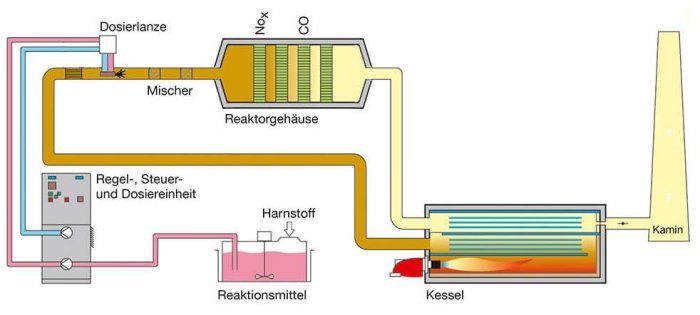

Catalytic exhaust and exhaust air cleaning: EWK Umwelttechnik has been building systems for air pollution control and purification of exhaust gases for decades. The SCR (selective catalytic reduction) process is successfully used to reduce pollutants: Process exhaust, Combustion gases.

Most popular related searches

combined heat and power system

combined heat and power

heat and power

diesel engine

gas cleaning

incineration

incinerator

gas engine

carbonization

biofuel

Modular design

- The reactor housing is made of stainless steel in a modular system with integrated insulation.

- This allows individual placement depending on the type of pollutant and concentration of pollutants.

- individual adaptation to structural conditions.

- compact and cost-effective design.

SCR catalyst technology is characterized by:

- low maintenance costs

- High operational reliability

- long service life

- simple operation

- Low operating costs

- good retrofitability for old plants

Advantages of using SCR technology with urea as a reaction agent

- Urea is non-toxic. Transport and storage are trouble-free

- NOx sales rates of over 98 are possible

- no or negligible reaction by-products

- low ammonia slip

- Incinerators

- Chemical, pharmaceutical industry

- Process exhaust

- Solvent disposal

- Stainless steel tining systems

- Gas, diesel engines

- Residual recycling plants

- Incinerators

- Glass tubs

- Combined heat and power plants

- Explosives dissolocation

Both the combustion of biofuels as well as fossil fuels and industrial waste (solvent, sewage sludge, explosive, waste, industrial residues, etc.) also produce large quantities of

- Nitrogen oxide NOx

- Carbon monoxide CO

- Hydrocarbons CmHn

- Dioxins/furans

With the SCR catalyst technology, these high-efficiency air pollutants can be converted to N2,CO2 and H2O.