- Home

- Companies

- Anand Seamless Tubes Pvt. Ltd.

- Products

- Anand - Extruded Fin Tube

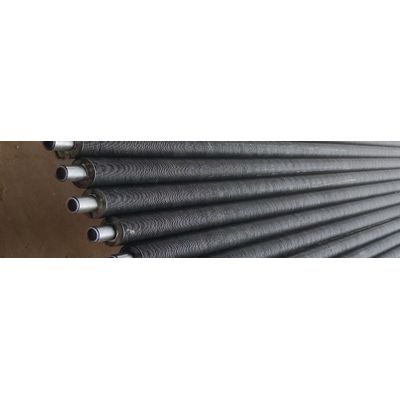

Anand - Extruded Fin Tube

The Extruded Fin Tubealso known asBimetallic Fin Tubeis one of the most preferred finning processes for various applications. The fins are manufactured by Extruding the Fins on the Aluminum Muff Tube which is made to Fit with close tolerance over the Base Tube.

The Extrusion takes place on a Continuous Fin Extruder with Three Tooling rolls and extrusion takes place at high pressures in the range of 1200 psi. Because of the cold working process the Bond between the Tube and fin is flawless and hence gives excellent Heat Transfer Efficiency. At the same time the mechanical strength of the fins is also enhanced drastically.

These Fin Tubes find application in AIR FIN COOLERS, DRIERS, RADIATORS etc and are preferred in Industries like Food and Agriculture, Power Plants, Chemical Industries, Steel Plants, Chiller Plants etc.

-

Manufacturing Process:- Cold Extrusion

-

Fin To Tube Bond:- Excellent

-

Heat Transfer Efficiency:- Excellent

-

Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life)

-

Corrosion Protection:- Gives excellent corrosion protection to the base tube since it entirely covers the base tube (except bare ends).

-

Temperature Range:- Upto Maximum 300 Deg C

- Automobile Industries

- Heat Exchanger

- Boiler & Pressure Vessel

- Petroleum Industries

- Pharmaceutical Industries

- Condenser

- Oil & Gas Refineries

- Thermal & Nuclear Power Plants

- Chemical Industries

- Defense

- Hydraulic & Pneumatic Systems

- Dairies

- Fertilizers Industries

- Solvent Plant

- Sugar Industries

- Railways

- Textile Machinery

- Instrumentation