- Home

- Companies

- Envipro Engineering Pvt. Ltd

- Products

- Envipro - Flash Dryer System

Envipro - Flash Dryer System

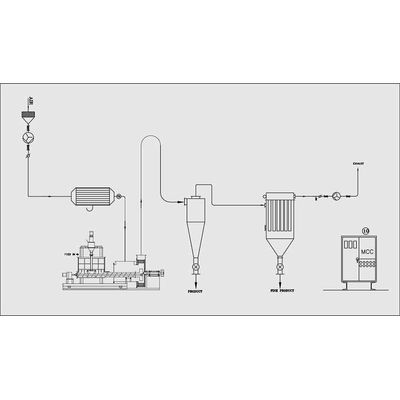

We are leading Flash Dryer System Manufacturers. Flash drying is suitable for drying of Wet material; in this process, hot air and the wet material are introduced simultaneously into the drying chamber and mixed with each other due to which drying of material takes place, usually, cage mill is used for the better surface area required for the drying.Flash Dryer System Manufacturers In Flash dryer systems the material retention time is very short. Flash drying is accomplished with a large quantity of air with active heat exchange while drying the material is transported simultaneously up to the air and material separation system; i.e. cyclone or bag filter. Flash Dryer System Manufacturers Prochem Systems ( India ) Pvt. Ltd. is leading flash dryer system manufacturers, traders, and suppliers. Our Manufacturer range also includes Rotary Dryer, Spray Dryer,Paddle Dryer, Spin Flash Dryer, Vibratory Fluid Bed Dryer System Manufacturers etc.

- Pharmaceuticals

- Chemical and Chemical sludge drying

- Pigment Industries

- Insecticide Industries

- Textile Industries and much more

- Less space required

- Capable of processing high capacities in a relatively small amount of space

- Often used as a pre-dryer to expand production capacity on existing lines

- High thermal flash drying efficiency

- Low maintenance cost

- Consistent product quality. Flash Dryer System Manufacturers For dispersion of material, de-agglomeration equipment, such as a Cage Mill or scatter is used

- Crushing of lumps is possible with addition of a Cage Mill to the flash dryer system

- If size reduction is not desired, a mechanical slinger is available for the flash dryer system to disperse sticky materials Pneumatic conveying while flash drying eliminates additional equipment

- High process gas temperatures possible for reduced size and cost

- For dispersion of material, de-agglomeration equipment