- Home

- Companies

- Pyro Green-Gas (formerly known as ...

- Products

- AirScience - Gas Dryers System

AirScience - Gas Dryers System

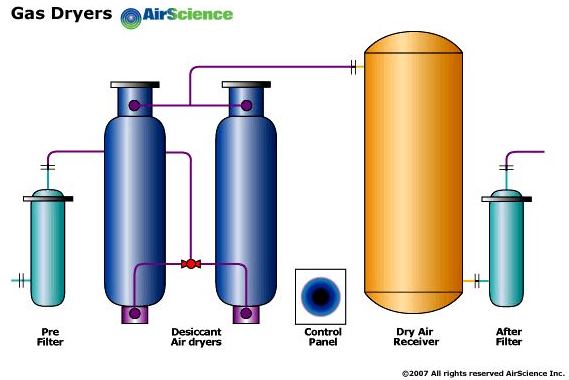

Wet process gas enters a coalescing pre-filter, then passes through the inlet valve assembly and is directed towards chamber 1 where the clean gas passes upward through the desiccant. Gas drying is doneby adsorption. Dry gas from chamber 1 outlet passes through the valve assembly and through the after-filter to the dry gas receiver tank. While gas is being dried in chamber 1, the desiccant in chamber 2 which has been humidified in the previous cycle, is being simultaneously regenerated. Chamber 2 is de-pressurized, in the downward direction, and the vent gas is released to atmosphere through a purge valve.

A controlled portion of dry gas is used to flush out the desorbed moisture from chamber 2 desiccant.When the regeneration is complete, the purge valve is closed and chamber 2 is slowly re- pressurized to line pressure for a smooth changeover. A drying period of 5 minutes provides an efficient dew point of -40°C or better. In regeneration process approximately 60 seconds are required for re-pressurization. AirScience Process Gas Heatless Desiccant Dryers are factory skid-mounted and pre-commissioned. They are fully automatic and require no operator. All operations take place automatically and Gas Purity remains consistent.