- Home

- Companies

- Marine BioEnergy, Inc.

- Products

- Giant Kelp - Macrocystis Pyrifera

Giant Kelp - Macrocystis Pyrifera

Giant Kelp (Macrocystis pyrifera) is one of the fastest growing producers of biomass. The open ocean is an immense, untapped region for collecting solar energy. Giant kelp does not grow naturally in the open ocean because kelp normally needs an attachment at about 10-20 meters of depth and also needs key nutrients that are available in deep ocean water or near shore but not at the surface in the open ocean. This concept proposes an economical system to provide a grid for attachment and access to nutrients, making it possible to farm kelp in the extensive regions of the open ocean.

If successful, this patented approach will grow kelp attached to large grids in the open ocean, each grid towed by inexpensive underwater drones. These drones will maintain the grids near the surface during the day to gather sunlight for photosynthesis. At night, the drones will take the grids down to the deeper, cold water where the kelp can absorb nutrients that are not adequate in the warmer surface waters. These kelp farms will also be taken to deeper water during storms or to avoid passing ships. Every three months, the drones will move the kelp farms to scheduled locations to rendezvous with harvesters.

Does not compete with food production for agricultural land, harm environmentally sensitive areas (such as deserts or marine reserves), or use fresh water, pesticides, or artificial fertilizers.

Kelp is relatively easy to process into drop-in fuels because it has no lignin and little cellulose2. Kelp is one of the fastest-growing primary producers with elongation rates ~30 cm/day3, and average photosynthetic efficiency in the range of 6-8%, much higher than terrestrial plant production at 1.8-2.2%4. Kelp stores over 1 Watt/m2 (averaged 24/7/365) of sunlight as chemical energy (~2.8 kg ash-free, dry weight per m2-year) , as observed in natural beds. 5,6

Kelp continues to grow year round especially if adequate nutrients are available, and the harvest is non-destructive so farms can be productive for years without replanting.

Near shore areas with natural upwelling of nutrients won`t produce enough biomass to make a significant impact on the nation`s energy needs. Many natural kelp beds are in marine reserves, or in recreational or commercial areas.

The production of underwater drones will be less expensive than one might expect because they will be made out of reinforced concrete and numerous subsystems are already available in production quantities (automated guidance & control, communications, batteries, pumps, sensors).

Kelp grown in the open ocean can utilize massive open ocean areas to supply an energy feedstock sufficient for the projected peak world population at the current U.S. per capita rate of energy consumption of ~9500W/person.

The Pacific Ocean offshore of the Western U.S. represents an immense, untapped solar collecting area and, if this effort is successful, will be the first deployment region for the commercial farm systems. Fast-growing kelp produces biomass year round and could provide a transformational solution to the need for millions of tons of feedstock per year.

The key test is: does a fast-growing kelp thrive when depth-cycled at night to absorb nutrients and surfaced during the day to absorb sunlight? The target species is giant kelp (Macrocystis pyrifera).

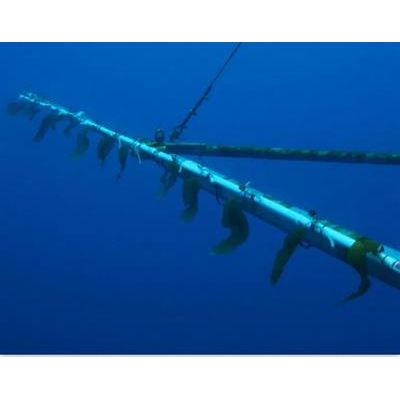

The first test has now been completed and depth-cycled kelps to 80 meters depth (272 feet). The Marine Biology team has collecting permits and collected juveniles with the first blade (leaf) but not formed the first pnuematocyst (floatation bulb formed and used by the kelp to float the plant upward to the surface and the sunlight). The Biologists collected enough juveniles for both the depth-cycling test and a matched control line. All juveniles were surfaced, weighed and measured and then deployed to either the test or control system.

The juvenile kelps were attached to an anchored buoy system which surfaced the kelps during the day and submerged them at night. The buoy is located in deep water with no nutrients in the top layer and abundant nutrients in the deeper water below the thermocline. Marine Biologists monitored the kelps and the water nutrients regularly. At the end of this first test, the biomass was weighed and compared to biomass from the control group.

In the open ocean, the top layer is nutrient poor and the kelp must absorb deep water nutrients to continue to produce biomass. If further experiments show that these results are repeatable, then open ocean farms towed by drone submarines can make abundant kelp available for carbon-neutral fuels.

As part of this effort, the Wrigley Institute has developed a kelp nursery to grow sporelings on artificial substrate (long lines). The nursery long lines will be subjected to depth-cycling and are part of the preparation for commercial deployment.

Research published by a team at Pacific Northwest National Laboratory has evaluated HydroThermal Liquefaction and Catalytic Hydrothermal Gasification (HTL/CHG) applied to Saccharina,1 a species of brown kelp similar to the Macrocystis considered for this project. The HTL was conducted in a continuous flow reactor at 350oC and 20 MPa. In contrast to fermentation, which often takes many days, the average residence time in the reactor is less than an hour. The output from this process was a liquid that gravity-separated into a biocrude and an aqueous fraction. About half of the original carbon in the feedstock was converted into the biocrude and just under half in the aqueous fraction. The aqueous fraction was then catalytically processed by CHG at the same temperature and pressure as the HTL. The CHG caused the carbon in the aqueous fraction to go to methane and carbon dioxide in approximately the ratio of 2:1 (respectively), with <1% remaining in the relatively clean waste water.

Some of this moderate heating-value gas will be used for the needed process heat. Part of the gas can also be used to produce the hydrogen (by steam reforming and water-gas shift) needed to upgrade the biocrude via hydrotreating. This creates a high-value crude oil equivalent. The biocrude coming out of the HTL process was found to have a C:H:O:S:N ratio of about 17.5:23:1:0.8:0.04. Hydrotreating of this biocrude will increase the H:C ratio closer to the approximate 1.9:1 value associated with desirable liquid fuels and will extract most of the remaining oxygen, sulfur, and nitrogen. The surplus methane from CHG beyond that used for process heat and hydrogen synthesis can be sold, or in a future version of the concept, used to power the harvesters so that all processing can occur at sea and the harvesters do not need to return raw kelp to dock. Oil tankers can be filled with high-value biocrude at the harvesting sites in the open ocean, making the whole process carbon-neutral in the global environment.