- Home

- Companies

- GIG Karasek GmbH

- Products

- GIG Karasek - Multi-Effect ...

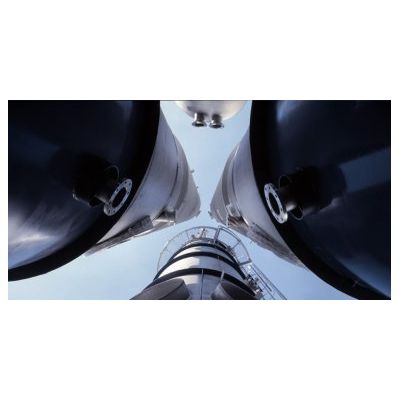

GIG Karasek - Multi-Effect Rectification System

The top vapors of the column working under the higher pressure heat the reboiler of the column working under the lower pressure

MVR

The top vapors of the column are being recompressed by a mechanical recompressor and are employed for heating the reboiler

TVR

Top vapors with higher pressure than the working pressure of the column serve as motive vapors for an ejector. The ejector recompresses the top vapors of the column. The recompressed top vapors are used for heating the reboiler.

The differences in boiling point between the top and the bottom of a column, and the thermodynamic properties of the top product are the criteria for the decision, whether one of the packages can be applied in your case or not.

Typical processes, the feed to GIG Karasek Rectification Systems may come from:

- Extraction of substances from biomasses or from plants

- Precipitation of high-molecular biological substances e.g. with isopropanol

- Solvent Crystallization (e.g. an organic solvent is being used to reduce the solubility of a valuable substance dissolved in water)

Typical clients are the pharmaceutical industries, fine chemical industries and producers of additives for food or cosmetics.

Multi-Effect Distillation

- There is low cost steam available which has to be used (e.g. from a steam turbine)

- The difference head to bottom temperature is too big for mechanical or thermal vapor recompression

- The product characteristics and the steam pressure available allow operation within the range of temperature required for the multi-effect system.

- Note: The system is not applicable for high vacuum distillation

TVR Distillation (thermal recompression)

- The top product is water only, or water with negligible content of organic substances.

- Or distillate can be easily evaporated in order to provide motive vapors for the ejector.

- The heating agent (steam or heat oil) is available at the necessary temperature level

- Low or moderate difference between top and bottom temperature

MVR-Distillation (mechanical recompression)

- Low or moderate difference between top and bottom temperature

- The outlet temperature of the recompressor should be below the temperature of self-ignition of the top vapors.

- The feed characteristics must allow an efficient heat transfer between the feed and the top and bottom stream.

- Note: Not applicable for high vacuum

- If applicable, excellently low energy consumption!