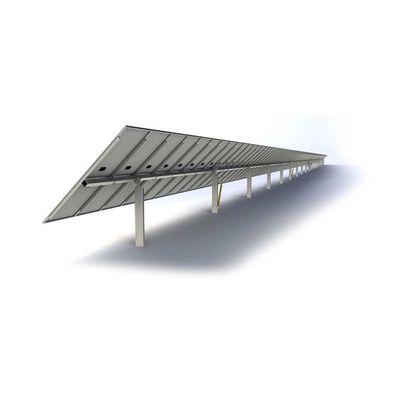

Mechatron - Model S5 -Horizontal Single Axis Tracker

The investment cost of an S5 is around 10% higher than that of an equal capacity fixed Photovoltaic(s)".">PV installation, while the power production increase is between 15% to 25%. As a result, if an investor has a fixed size license with an attractive feed-in tariff, he can invest more money, while enjoining a better IRR and NPV on the investment. If an investor has a fixed investment capital, the installed capacity will be around 10% lower, but the total production will be 5% to 15% higher, again pushing the IRR and the NPV of the investment higher. The S5’s design is based on our accumulated design knowledge and extensive field experience. Every detail has been thoroughly engineered to have the minimum impact to the levelized cost of electricity (LCOE).

Prepare For The Future

A tracker’s energy production curve is almost constant throughout the day, in contrast to a fixed PV installation that produces the majority of the energy during noon. In many countries, there is already a surplus of energy production in noon and a lack of energy production in the morning and the afternoon. This phenomenon will be intensified in the next decades, as solar energy increases its proportion in the electricity generation. Also after the end of the existing PPAs, the solar producers will lose the benefit of the feed-in tariff and will sell their energy at prices driven by the competition. Producers whose installations production curve have a better match to the demand will have an advantage during price negotiations. The S5 also reduces the CAPEX and the LCOE in installations that implement energy storage, since the increase in production hours equals a proportional reduction to the energy storage needs.

The S5 uses a hydraulic drive which despite its higher initial cost compared to electric drives, is the only safe choice for harsh environments (proven for decades in earth-moving machinery). The hydraulic circuit is isolated from the environment and the hydraulic oil is constantly filtered by a micro-filter. This makes the operation possible even in the thin dust of a desert, securing reliable and low maintenance operation for many years.

The S250 uses hydraulic axis drive, which despite its higher cost compared to other technologies, is the only safe choice for harsh environments (proven for decades in earth-moving machinery). The hydraulic circuit is isolated from the environment and the hydraulic oil is constantly filtered by a micro-filter. This makes the operation possible even in the thin dust of a desert, securing reliable and low maintenance operation for many years.

Depending on its length the tracker can have up to 6 actuators, where each actuator drives a 1/6 sector of the total length. This means that the maximum free rotating length on each side of the actuator is less than 12,5m. This very short free rotating length (unlike most other available solutions) gives exceptional torsional stability and zero backslash in alternating eccentric loads which usually occur during extreme wind conditions. This high torsional stability eliminates the need for stabilizers or shock absorbers.

All moving joints are made from a combination of stainless steel and bronze components and they do not require any kind of maintenance throughout the service life of the machine.

A change of the hydraulic oil and filter is required every 5 years.

All drive and control components can be removed and replaced in a few minutes, without disrupting the operation of the rest of the plant and without the need to dismantle the table.

- Type: Autonomous, horizontal single-axis solar tracker (rotation axis orientation south to north parallel to the ground)

- Range of motion: -47° to +47°

- Maximum surface area: 600 m²

- Possible Foundations:

- Rammed pole

- Concrete pile

- Concrete ballast

- Direct mounting on structures

- Min. distance from ground during operation: 0,37 m

- Max. height during operation: 3,41 m

- Ground coverage ratio: adjustable (recommended 50%)

- Max north-south field slope: 15°

- Unlimited east-west field slope

- Autonomous design using solar power

- 0,1 kWh battery included

- No need for connection to the main power grid

- Type: Hydraulic

- Maintenance:

- Visual annual inspection

- Hydraulic oil and filter change every 5 years

- Tracking method: Astronomical algorithm

- Tracking accuracy: 1°

- Measuring system: Inclinometer

- Backtracking: Yes

- Monitoring and remote handling: Full, in real time through the Internet

- Plug & Play: uses GPS for time and location

- Wireless communication, no need for bus wiring

- Active Safety Features (Stow)

- Wind speed protection

- Snow load protection

- Operating conditions: up 50 km/h at any tracking angle and wind orientation

- Drive: Hydraulic parts sealed from the environment. Able to operate in desert environment and in any combination of dust and moisture

- Structural steel elements: Hot-dip galvanized

- Joints: Dry slide stainless steel spherical bearings (no maintenance required)

- Operation temperature range: –20 °C to +60 °C

- Snow rating: 160 kg/m²