- Home

- Companies

- Kapa Engineering S.r.l.s

- Products

- Feeder - Model Hefaistus Nature - ...

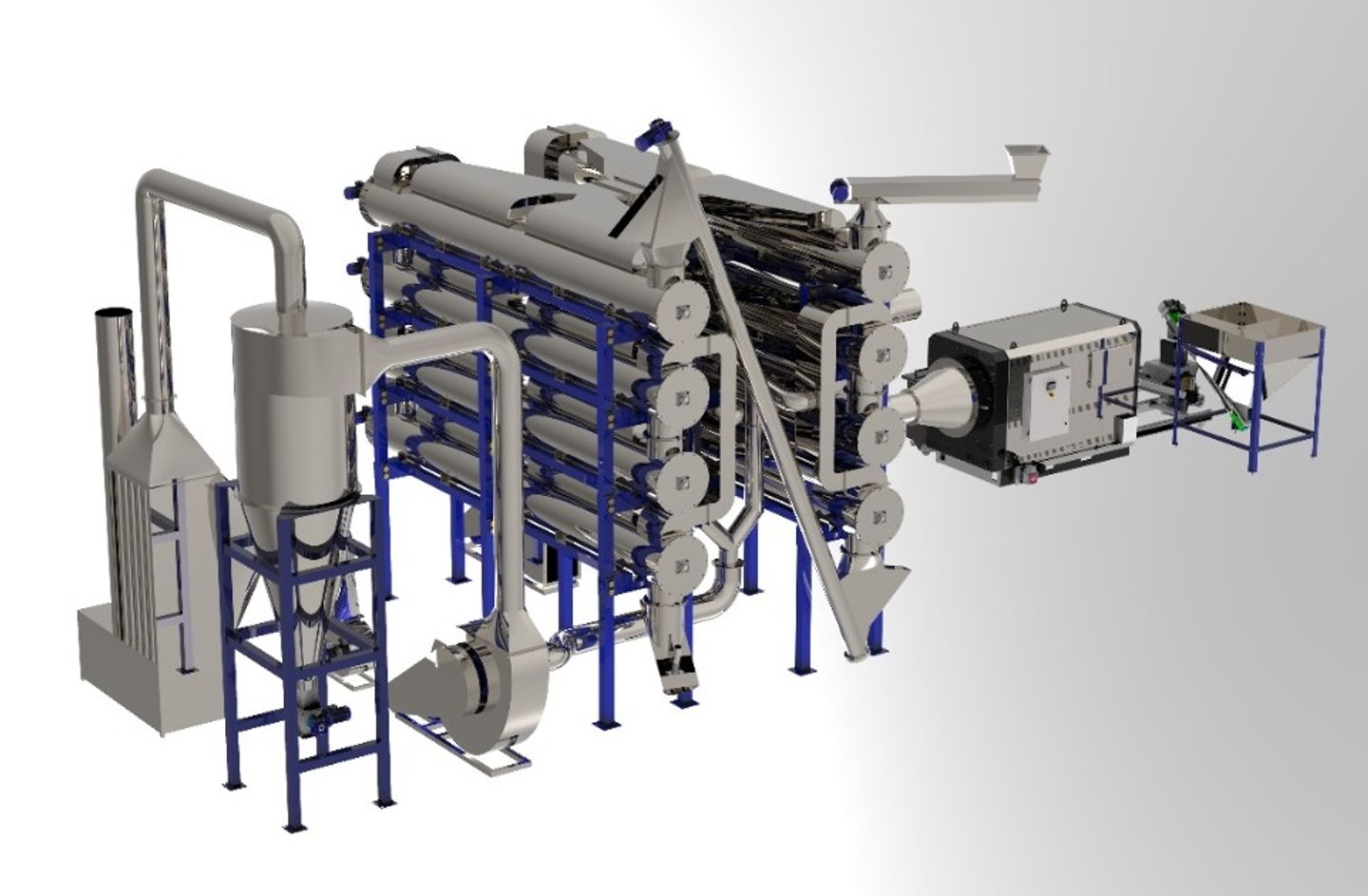

Feeder - Model Hefaistus Nature -Incinerators

The HEFAISTUS incinerator by Kapa Engineering has been designed to ensure both personnel safety through equipment and the environment itself. Therefore, physical concepts have been thought out and applied in this project uniquely and meticulously.

The design of the primary combustion chamber, with the correct positioning of the burners, has been developed to achieve the highest possible combustion efficiency. Thus, the cylindrical chamber with burners positioned at the top ensures that no clogging or obstruction issues occur with the air and/or fuel feeders, depending on the type of waste to be incinerated. It also ensures that all residues come into contact with the oxidizing zone of the flame, ensuring a gradual and complete combustion of all waste inside, resulting in complete conversion into inert ash.

Within the chamber, the gas movement process occurs according to precise physical concepts: the increase in temperature generates an expansion of kinetic energy and, consequently, a reduction in pressure. Therefore, the upper part of the primary chamber features a low-pressure characteristic.

In addition to the pressure differential created by the burners, heat is conveyed internally onto the waste to be incinerated. Similar to a pan on the fire, heat attacks the waste through convection and conduction, as illustrated below.

"The vortex intentionally created by the airflow within the combustion chamber is responsible for the turbulence inside it. The images on the left illustrate these turbulences within the primary chamber of HEFAISTUS, in its front and side sectional views."