- Home

- Companies

- Nexus Metal & Alloys

- Products

- Inconel - Model 800 - Nickel Alloy

Inconel - Model 800 -Nickel Alloy

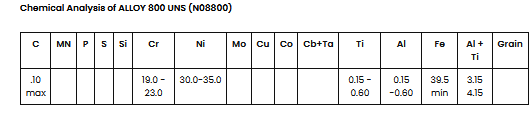

Incoloy alloy 800 is a widely used material of construction for equipment that must have high strength and resist carburization,oxidation and other harmful effects of high-temperature exposure. (For high temperature applications requiring optimum rupture and creep properties, Incoloy alloys 800H and 800HT are used). The chromium in the alloy imparts resistance to oxidation and corrosion. The high percentage of nickel maintains an austenitic structure so that the alloy is ductile. the nickel content also contributes general corrosion, resistance to scaling and stress-corrosion cracking.

Incoloy® alloy 800 is used in a variety of applications involving exposure to high temperatures and corrosive environments. It is used for heat-treating equipment such as baskets, trays and fixtures. In chemical and petrochemical processing the alloy is used for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in home appliances for sheathing of electric heating elements. In the production of paper pulp, digester liquid heaters are often made of alloy 800. In petroleum processing , the alloy is used for heat exchangers that air-cool the process stream.

Incoloy 800® is a nickel-chromium alloy with good strength and excellent resistance to oxidation and carburization. The alloy maintains stable structure during exposure to high temperature, therefore incoloy 800® has good corrosion resistance to many acidic environments.

Available forms are Inconel 800 Seamless Pipe, Inconel 800 Welded Pipe, Inconel 800 Seamless Tube, Inconel 800 Welded Tube, Inconel 800 Round Bars, Inconel 800 Wire, Inconel 800 Sheet, Inconel 800 Plate, Inconel 800 Forgings, Inconel 800 Pipe Fittings and Inconel 800 Flanges.

Description: Inconel 800 is an iron-nickel-chromium alloy with moderate strength and good resistance to oxidation and carburization at elevated temperatures. It is particularly useful for high-temperature equipment in the petrochemical industry because the alloy doesn`t form the embrittling sigma phase after long time exposure at 1200 Degrees F (649 Degrees C). Excellent resistance to chloride stress-corrosion cracking is another important feature of Inconel 800.

Alloy 800H is a solution heat treated (2100 Degrees F/1150 Degrees C), controlled-carbon version of Alloy 800 with improved elevated temperature properties. It has improved creep and stress-rupture characteristics in the 1100 Degrees F (593 Degrees C) to 1800 Degrees F (982 Degrees C) temperature range.

Applications: Typical applications for Alloy 800 and 800H are - Heat exchangers and process piping; carburizing fixtures and retorts; furnace components; electric range heating-element sheathing; extruded tubing for ethylene and steam methane reforming furnaces; ammonia effluent coolers.

- Sheet / Plate ASME SB-409 / AMS 5877

- Round Bar ASME SB-408 / AMS 5766

- Pipe ASME SB-407 / ASME SB-829 / ASME SB-514 / ASME SB-775

- Tube ASME SB-407 / ASME SB-829 / ASME SB-515 / ASME SB-751

- Fittings ASME SB-366

- Forgings ASME SB-564 / AMS 5766