- Home

- Companies

- Lectrodryer, LLC

- Products

- Lectrodryer - Model Type Gas B - ...

Lectrodryer - Model Type Gas B -Industrial Gas Dryers

The Type GAS-B Lectrodryer is specially designed for low pressure gas service, dissociated ammonia service, removal of moisture from cylinder gasses, and for the removal of non-condensable contaminants from all process gas. It is a solid adsorption heat-reactivated gas dryer in a dual tower design that provides efficient and continuous operation. The GAS-B was carefully developed to offer low initial cost, low operating cost and requires little or no maintenance.

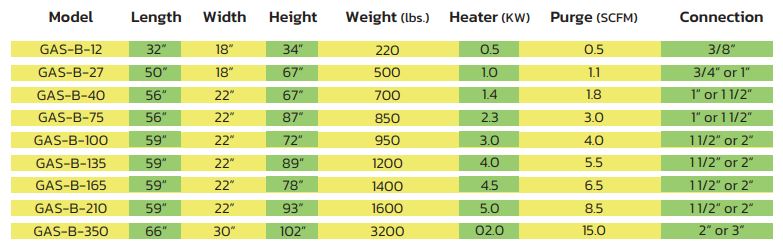

The Type Gas-B Lectrodryer is available in a full range of sizes and capacities to meet the individual drying needs of your particular operation.

Standard Type GAS-B Features

- Allen Bradley PLC

- Electric reactivation heaters to utilize the optimum capacity of the desiccant

- Heaters are designed with low-watt density and thermostatic over-temperature for added durability (except Gas-B-12).

- Lubricate 4-way plug valves with an interlocking valve drive mechanism with air piston operator and solenoid controls. No copper or brass in contact with process stream.

- Dial thermometer measures reactivation exhaust temperatures

- Calibrated direct-reading purge flow meter with adjustable micrometer valve and reactivation indicator lights

- Carbon steel pressure vessels

- Relief valves on each adsorber

- Locally mounted pressure gages

- ASME Code designed except GAS-B-12

When one column dries the gas as it passes through, the other column is reactivated by a small portion of the dried outlet gas at the same time. This procedure is then reversed on a predetermined time cycle to provide through removal of water and various other constituents.

The cycling state is continuous and fully automatic. No manual attention is required for switching adsorbed columns. The positive-drive, 4-way valves automatically reverse the adsorbers. The controls are handled by a programmable logic controller (PLC) which allows a full range of adjustments and options. Since the GAS-B has so few moving parts, there is less chance of a malfunction, or does the GAS-B require the time-consuming and costly adjustments that are necessary with other gas drying units.

By using specialized adsorbents, like molecular sieve, the GAS-B can also dry air and gas to very low moisture contents below –100°F. It can remove even the slightest trace of non-condensable contaminants such as residual ammonia, carbon dioxide, hydrogen sulfide, carbonyl sulfide, and various mercaptans from other fluids.