SINC Thermal LLC

SINC Thermal - Industrial Immersion Furnaces

FromSINC Thermal LLC

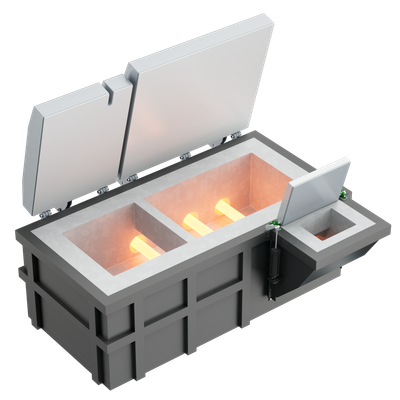

SINC Thermal LLC offers industrial immersion furnaces designed to provide efficient heat treatment for a range of metalworking processes. These furnaces are essential in operations requiring uniform heating and thermal management. Built for durability and precision, the immersion furnaces are tailored to meet the demanding needs of manufacturing environments, ensuring optimal energy consumption and thermal efficiency. Capable of handling various metals and alloys, these furnaces maintain consistent temperature controls and improve overall process performance. By incorporating advanced thermal technologies, SINC Thermal's immersion furnaces are especially beneficial in processes such as annealing, hardening, and tempering. They are engineered to support rigorous industrial standards, making them a reliable choice for companies focused on high-quality heat treatment solutions.Most popular related searches

electric immersion heater

energy efficiency

furnace

industrial furnace

immersion heater

gas fire

energy consumption

energy efficiency improvement

electric heater

SINC Thermal’s holding furnaces overcome many of the traditional problems associated with radiant or gas fired units by using immersion heating elements to submerge the heat source and use the principle of conduction to transfer heat directly into the molten aluminum, offering the most efficient heat transfer method for holding temperatures up to 1380°F (~750°C).

Electric immersion heaters offer the highest heat transfer, and energy efficiency with minimal dross formation. These features combine consistent and reliable operation while optimizing the service life of the refractory lining.

SINC’s compact design allows easy access for cleaning, quiet operation, and low heat loss for boosting energy efficiency while also improving the working environment for your operators.

Electric immersion heaters offer the highest heat transfer, and energy efficiency with minimal dross formation. These features combine consistent and reliable operation while optimizing the service life of the refractory lining.

SINC’s compact design allows easy access for cleaning, quiet operation, and low heat loss for boosting energy efficiency while also improving the working environment for your operators.

- Immersion heated furnaces also improve metal quality and reduce cleaning operations by maintaining uniform temperature and reducing oxides formation.

- Furnaces can be configured to suit customer and installation requirements with left hand, right hand or central fill points.

- The filling pocket is designed to promote metal flow and avoid stratification without unnecessary disturbances.

- Heating element position can be configured to suit customer installation.

- Horizontally installed through the side wall (left or right through the bath end wall, or vertically installed in the bath lid.

- A variety of options are also available to accommodate different operating conditions and temperatures.