- Home

- Companies

- Jansens Aircraft Systems Controls Inc. ...

- Products

- JASC - Liquid Fuel Check Valve

JASC - Liquid Fuel Check Valve

The JASC Liquid Fuel Check Valve improves fuel system reliability on dual fuel turbine engines. JASC’s high-flow, zero-leak Liquid Fuel Check Valve is designed to operate with fluids including Stoddard solvent, jet fuels, hydraulic oil, synthetic oil and air.

JASC’s Liquid Fuel Check Valve utilizes fluid dampening to provide stable valve operation from crack to full flow operation. The inverted spool within the JASC Liquid Fuel Check valve makes use of a Helmholtz Resonator, which dampens the effect of fuel pressure imbalances, providing greater operation stability than a traditional ball and spring liquid fuel check valve. The inverted spool meters fuel and holds a specific delta pressure across the valve, allowing the valves to open uniformly and simultaneously.

To ensure the Liquid Fuel Check Valves meet the customer’s unique performance specifications, JASC rigorously tests each valve. The check valves are contamination tolerant, chatter resistant, and have a ANSI Class 6 zero-leak seal in the check direction.

JASC Liquid Fuel Check Valves can be refurbished indefinitely, returning the valve to its original operating condition. This lowers total cost of ownership significantly over liquid fuel check valves that can’t be refurbished.

- Leak in Flow/Check Direction ANSI Class 6 Seal

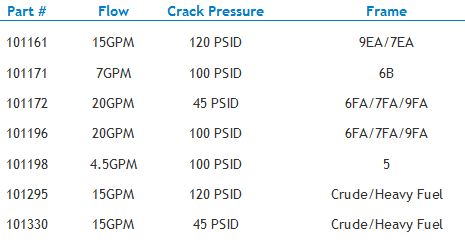

- Flow Various available

- Operating Temperature 600 °F

- Stable Operation Helmholtz Resonator

- Inlet Temperature 60 °F to 250 °F

- Inlet Pressure 0-1225 PSIG

- Crack Pressure Various available

- Soakback Temperature 700 °F

- Maximum Ambient Temperatures 400 °F

- Check Pressure Up to 300 PSIG

- Maximum Pressure Drop Various available

- Construction Materials .Stainless Steel

- Weight 1 lb