- Home

- Companies

- STELA Laxhuber GmbH

- Products

- Stela - Model Type BTF-L - Layer Belt ...

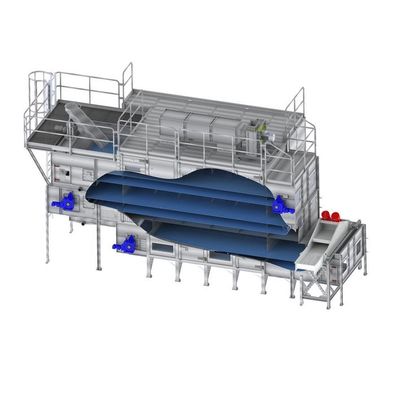

Stela - Model Type BTF-L -Layer Belt Dryer

The belt dryer type BTF-L is a layer dryer for food and pet food applications. Layer dryers combine several belts on top of each other in one dryer housing.

Heating

BTF-L dryers can be realised with a wide variety of heat generators and heat carriers. The most suitable are:

Heat carrier

- Hot water, steam or thermal oil

Heat generators

- Gas, oil, biomass or electric boiler

- Gas burner, direct or indirect

Material handling and output

Depending on the requirements, the appropriate technology is selected in consultation with the customer.

The product is typically placed on the dryer belt via swivel chutes, swivel belts, product chutes, vibration chutes and similar systems.

After the drying process, the product leaves the dryer via vibrating chutes, slides, discharge conveyors or screws.

A large drying area is realised in a small installation space.

- The specific costs per square metre of belt area are reduced.

- The required installation space is reduced by the number of belts, e.g. by a factor of 3 for a 3-belt dryer. This makes it easier to install the dryer in buildings/halls.

- The compact installation space reduces heat losses via the outer shell.

It is possible to ventilate several belts with the same air flow.

- The number of fans and heat generators can be reduced. This reduces investment costs and electricity demand.

- The air is better hydrated as it passes through several belts in a row. This increases the thermal energy efficiency.

- The exhaust air flow rate can be reduced.

BTF-L dryers are suitable for products with a medium or low specific water evaporation. Products that slowly release water need less air to dry but may need more time to dry. The compact design allows high belt areas and thus high dwell times to be realised. The ventilation intensity is lower compared to a stage dryer.

Typical applications for the BTF-L dryer are nuts, cereals, extrudates as well as fruit, berries and vegetables.