- Home

- Companies

- STELA Laxhuber GmbH

- Products

- Stela - Model Type BTF - S - Layer Belt ...

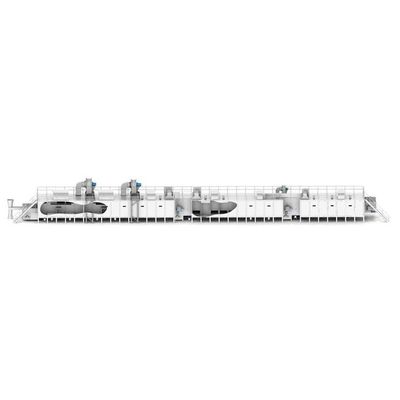

Stela - Model Type BTF - S -Layer Belt Dryer

The belt dryer type BTF – S is an efficient stage dryer, which was specially designed for use in the food and pet food sectors. Stage dryers are characterised by the arrangement of several belts (stages) one behind the other.

Customised heating options

BTF - S dryers can be operated flexibly with different heat generators and heat transfer media. The most suitable are:

- Heat generators

- Gas, oil, biomass or electric boilers

- Gas burners, direct or indirect

Heat carriers

- Hot water, steam or thermal oil

Efficient airflow and individual adjustment

Air can flow through the process belts from above as well as from below. The belts can be zoned over the belt length. The dryers are available both as exhaust air and recirculation air systems. Optionally, exhaust air heat recycling can also be achieved.

Optimal material handling and output

We offer a variety of techniques for material infeed and discharge, which we select in consultation with you according to your requirements. The product is typically fed in via swing conveyors, swing belts, product conveyors, vibratory conveyors and similar systems. After the drying process, the product leaves the dryer via vibrating conveyors, slides, discharge conveyors or screws.

- Each belt is placed in its own dryer housing and offers generous installation space.

- The extended installation space allows high air velocities and thus significant water evaporation per square metre of belt surface.

- The design allows higher bulk heights, which enables more efficient use of the belt area.

- Seamless integration of reversers optimises dryer performance and ensures consistent product quality.

- The large installation space facilitates cleaning and maintenance of the dryer.

The belt length of each stage can be individually defined, typically using staggered lengths to ensure optimal drying. This leads to the following advantages:

- Reduced investment and energy costs

- Increased bulk heights

- Reduction of material shrinkage

Explanation:

In the back drying sections, many drying products allow significantly higher bulk heights. This is because they lie more loosely with increasing degree of dryness, are more stable and can thus still be ventilated well even with higher bulk levels. To increase the bulk height, each belt runs slower than the previous one. With the same dwell time per belt, each belt can be shorter.

BTF – S dryers are suitable for products with a high water evaporation. Products that release water quickly require a lot of air for drying. Due to the large installation space, the necessary air quantities can be led evenly through the product.

Typical applications for the BTF - S dryers are leafy crops: Herbs, grasses (sea grass, wheat grass) and vegetables: onions.