- Home

- Companies

- Lectrodryer, LLC

- Products

- Lectrodryer - Model Type-BA - ...

Lectrodryer - Model Type-BA -Industrial Gas Dryer

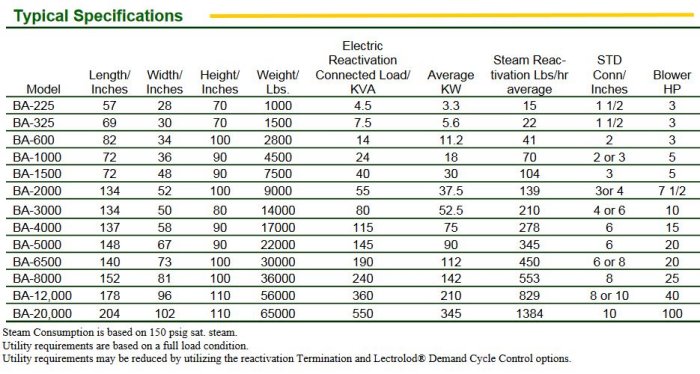

The BA is a regenerative-type dryer for compressed air or gas drying. It has a dual tower system suit-able for either steam or electric reactivation, fully automatic in operation. A dependable reactivation blower is provided, thus eliminating the need for the process gas from the steam being required for reac-tivation. And it can provide gas or air with a dew point of -40ºF or below.

The BA’s absorbers are reactivated by heating the flow of reactivating air to drive off moisture from the bed. The reactivating air is taken from the atmos-phere so there is no loss or waste from the main stream. And heating can be accomplished with ei-ther steam or electricity. Automatic Operation The Type-BA Lectrodryer is a fully automatic unit supplying a continuous flow of dry air or gas. It re-quires very little maintenance, except for occasional lubrication. The reactivating air is taken from the atmosphere, heated and sent through, eliminating the loss or waster of process gas. The BA, con-trolled by a timer, runs on a normal 8-hour NEMA cycle consisting of 4 hours on drying, 3 hours on heating, and 1 hour on cooling. The flow pattern is determined by two mechanically interlocked four-way valves for positive flow direc-tion. The four-way valves are activated by an air motor with solenoid controls. And depending on the application, desiccants can either be activated alu-mina, silica gel, sorbead, or molecular sieve.

The Type-BA Lectrodryer is a fully automatic unit supplying a continuous flow of dry air or gas. It requires very little maintenance, except for occasional lubrication. The reactivating air is taken from the atmosphere, heated and sent through, eliminating the loss or waster of process gas. The BA, controlled by a timer, runs on a normal 8-hour NEMA cycle consisting of 4 hours on drying, 3 hours on heating, and 1 hour on cooling.

The flow pattern is determined by two mechanically interlocked four-way valves for positive flow direction. The four-way valves are activated by an air motor with solenoid controls. And depending on the application, desiccants can either be activated alumina, silica gel, sorbead, or molecular sieve.