- Home

- Companies

- G-Team, a.s.

- Products

- Model TR 320 - Steam Turbine

Model TR 320 -Steam Turbine

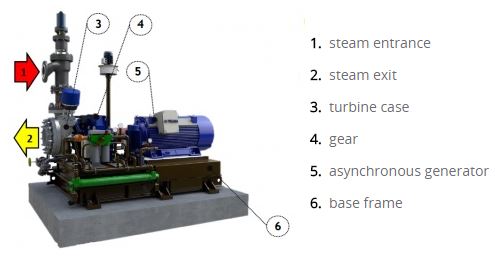

Steam Turbine 320 is designed for fueling generators and for electricity production. The Stator of TR 320 is connected to the gear, which reduces the rotations of the turbine wheel to rotations of the electric asynchronous generator. On the base frame, which also includes a complete oil kit, you can find the gear, which is connected to the turbine with a flexible link. Impermeability of the steam system is assured through a special contact valve.

The steam turbine automatically reduces the pressure of steam from higher value to the required lower value. The generator electricity output is tied to the amount of steam.

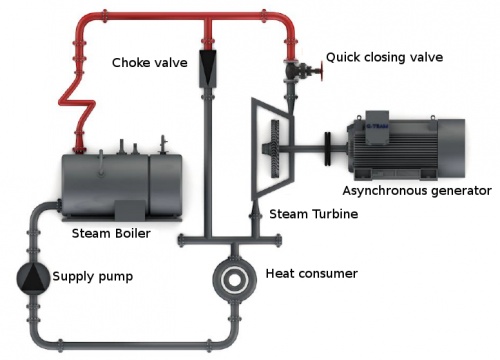

On the steam turbine schema above you can see the easy set up. The priority is with generating heat, in our case steam in the boiler for the current technology. The steam travels to the steam divider and then is reduced to the required pressure at the reduction station. The Micro Steam Turbine is connected in parallel to the steam reduction station in order to increase the efficiency of the whole heating circulation.

- For Mechanical drive: Yes

- For powering generator: Yes

- With an integrated gear: Yes

- Input steam pressure max. [MPa]: 9.0

- Input temperature of steam max. [°C]: 550

- Output steam pressure max. [MPa]: 2.5

- Generator output max. [kW]: 700

- Generator rotations [rpm]: 3000

Make yourself familiar with the advantages of steam turbines from G-Team. Their merits include a quick return on investment and a high efficiency, as they make use of excess heat that would normally go to waste.

Earn Money, Where Others Loose it. Create a New Source of Energy From Your Excess Steam.

The delivery of a complex solution reduces your installation costs. Our turbines are easy to operate and highly automated.

- Minimal installation size

- High heat efficiency in the range of 85% - 93,5 %

- Lifespan of at least 25years > even more efficiency

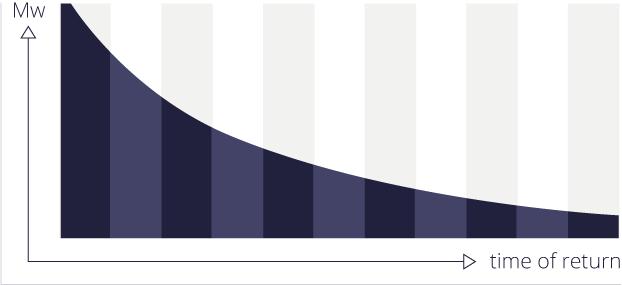

The Payback Period is Usually Under 5 Years

The payback period is influenced by the power of the steamturbine, its placement in the system and by any other personal request that you may have. However we can always guarantee a good ratio of price and benefits.

Efficiency

Making Use of Even the Smallest Sources of Steam

Small steam turbines use the energy from excess steam that would otherwise be wasted, therefore saving money by producing electricity.

Low Instalation Cost

Compared With Normal EPC Units, Our Delivery Costs are Much Lower.

Due to the complex solution, there are no extra construction costs for adding further devices. The costs can further be reduced, depending on the simplicity of installation which reflects your individual needs.

Simplicity

Our Turbines are Simple – Easy to Set Up and Easy to Use.

- a simple constructional solution

- a complete delivery on the base frame together with the oil kit

- no need for an additional supplier of extra services

- no need to install further devices to process the steam

- minor repairs are simple enough to be handled by your own technical department

High Automation

Due to a high automation, operation and maintenance of the steam turbine is simple. The easy operation is supported by a swift delivery of spare parts and a fast and cheap servicing in comparison with foreign suppliers.