- Home

- Companies

- Dizayn Group

- Products

- Dizayn - Model Pe 80 - Natural Gas Pipe ...

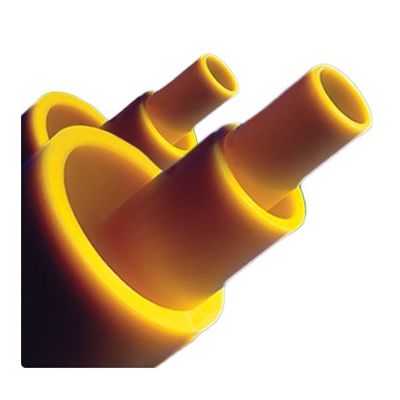

Dizayn - Model Pe 80 -Natural Gas Pipe and Fittings

PE80 natural gas pipes are used in the 4 bar pressurized regions of the natural gas lines. The natural has lines consist of 20 bar steel pipe, 4 bar intermediary line and 0.4 bar indoor lines. The polyethylene pipes with the composite structure in the 20 bar regions are started to be used for trial purposes. Its usage will become widespread after the standards are developed. The studies on the indoor composite pipes which will not affect from the fire are still going on.

Polyethylenes are divided into 3 groups according to their densities as Low Density, Medium Density and High Density. Although the pipe resistance and stiffness increase from the bottom to the top, in contrast, its flexibility and impact strength increase. Because the natural gas pipes are more flexible and their impact strength are higher than the high density ones, they are recommended.

Natural gas pipes are in PE80 class. The environmental strength value to be reached in the medium density is 8.0 MPa for now. When this level increases, the wall thickness will decrease and the fluid quantity passing through will increase. Because these pipes are from SDR11 class, when they are used for water, they can be used at 4 bar pressure in the natural gas line by changing the safety coefficient from 1,25 to 2,5 when used in PN 12,5 bar. Because the polymer chain is effected from the hydrocarbon structures, the safety coefficient is selected as high.

Because the pipes can be produced as a coil, they provide advantages in furnishing. Because the welding quantity decreases, the short lines can be furnished and they provide fitting and workmanship savings.

In order to cancel out the natural gas leakage probability from the weld, only electrofusion welding is used which is the most safe welding method. The current is passed from the copper wires which are placed inside the fittings. The wire in which the current is passed is heated. The released energy melts the plastic. The volume of the melted plastic increases and melts the pipe by contacting with it. The molecular welding is performed with the pressure strength which is formed by the compaction in the intermediary region. It does not get harmed in earthquakes with its flexible structure and it eliminates the explosion risk.

PE80 Natural gas pipes are manufactured on the machinery group called extruder track. The pipe production interval is Ø25-500 mm. The electrofusion fittings are produced by forming with mould in the injection machines. Placing copper in the electrofusion fittings make the fittings complexed. It is very important not to contact the wires with each other in order to perform the welding process.

After the oxide layer on the external layer of the pipes are taken, the fittings are covered on the pipes. The cables of the welding machine are attached to the metal pin on the fittings. After being read with the barcode, the welding is done according to the welding parameters in the memory of the machine. The expansion of the polyethylene from the spaces next to the pin shows that the welding is healthy. This is the most expensive and most safe welding method with the width of the welding region and not leaving any processes to be done for the employee.

- It is not affected by the earthquake by its flexible structure.

- It keeps its flexibility when the temperature decreases to -40 °C.

- Can be used on the building site as coil.

- Show high resistance to chemicals.

- Does not face corrosion by the fluid inside and by the structure of soil outside.

- It is light as 1/8 of steel as its volume being 0.940 gr/cm3.

- It can be combined out of channel and then released to channel. Decreases the excavation amount.

- It dos not require the ground to be sensible excavated progressively.