- Home

- Companies

- Guntamatic Heiztechnik GmbH

- Products

- Guntamatic-Heiztechnik - Model 30/40/50 ...

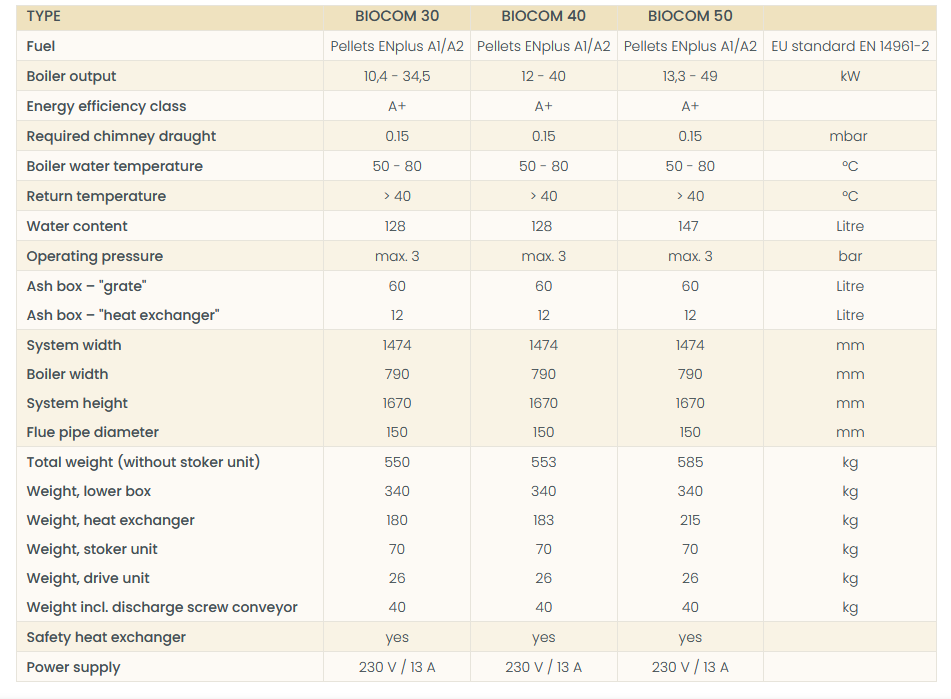

Guntamatic-Heiztechnik - Model 30/40/50 KW -Pellet Heating System

Biocom heating systems with industrial step grate technology deliver maximum economy with minimum emissions. These boilers can operate with wood pellets of varying quality.

AUTOMATICALLY HEATING WITH ECONOMY

- Ecological and economical heating convenience

- Self-cleaning industrial step grate for adjusting the ember bed size and boiler output without generating slag

- Clean primary air slots and optimum combustion through moving step grate technology

- Up to 95 % efficiency

- Self-cleaning tube bundle heat exchanger ensures long operating times without maintenance or cleaning measures

- Automatic adjustment of the fuel charge, grate speed and air intake

- Suitable for pellets class ENPlus A1 and ENPlus A2

- Ash screw conveyor and moveable ash box or fully automatic vacuum ash discharge into a 200 litre drum (option) for the highest cleaning convenience

- Well thought-out and user friendly interface with touchscreen

- Control by mobile (option)

- High grade components for maximum operational reliability

- Multi-stage safety concept through stoker unit controlled by lambda probes, protects against back burning and unpleasant surprises

- First class spare parts service from our own production

- Modular pellet discharge concept, suitable for almost every situation

- Robust, gentle screw conveyor system for high operational reliability

- Minimum power consumption thanks to energy efficient discharge

- Extremely robust pellet discharge screw conveyor with sprung arm agitator

The wood pellets are gasified on the industrial step grate, where primary air is supplied at an ember bed temperature of around 800 °C. The amount of combustion air and fuel charge is regulated by means of a lambda probe, so that the system achieves a level of efficiency of up to 94 %. With the aid of secondary air, the generated combustion gases are cleanly and efficiently converted into energy in a large rotating combustion zone.

FULLY AUTOMATIC CLEANINGConventional pellet heating systems require frequent cleaning. The Biocom system, on the other hand, cleans the combustion chamber, heat exchanger and grate area automatically. The large ash box reduces the remaining effort to a minimum. Only the general cleaning needs to be carried out manually.

PERFECT STORAGEGuntamatic storage systems, with vacuum delivery systems employing dosing screw conveyors, are highly durable and reliable. When the fuel is completely used up, there is no need for the annual storage room cleaning. Depending on requirements, a high grade steel/mesh hopper or sloping floor storage room with discharge screw conveyor are available.

PIONEERING OPERATING CONCEPTHighly advanced control technology enables you to regulate your interior climate, the system and storage room functions automatically. Individual adjustments can be made easily via the ergonomic touchscreen controller, a room control station (if installed) or an app on a smartphone.

DURABLE QUALITYBiocom systems are particularly reliable in operation and meet the highest quality requirements. They are made entirely in an ultra-modern factory in Austria, using exclusively selected, quality materials. In this way, customer satisfaction is guaranteed for years to come.