POZZI LEOPOLDO SRL

- Home

- Companies

- POZZI LEOPOLDO SRL

- Products

- POZZI - Model RHeX - Rotating Heat ...

POZZI - Model RHeX -Rotating Heat Exchanger

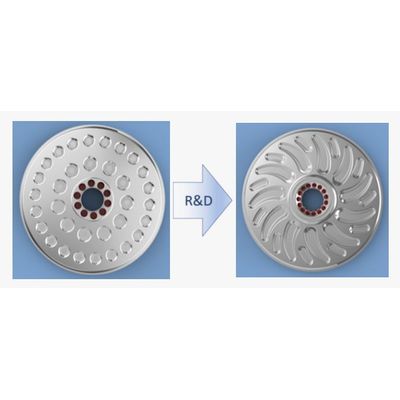

Evolution is a function of time. After years of undisputed success, the initial concept of rotating heat recovery systems developed with the RCR in thousands of worldwide successful plants has given birth to its latest flavour: the RHeX. Modular disks are no more welded to each other, they are simply mounted on a shaft, allowing substitution. More compact footprint, together with the novel “pushing action“ generated by the new disk design make it the easier to install and more efficient rotary exchanger ever.

Most popular related searches

The new RHeX model offers several advantages over its predecessor:

- Lenticular shells are no longer welded one to the other: the new design offers modular units which can be mounted freely on the supporting shaft. They can be, thus, removed and interchanged.

- The new patented blade design of the disk dimples allows for a positive "pushing” action on the effluent, making the unit even more suitable for thick and heavy fluids, further reducing the generated pressure loss.

- The reticular structure of the dimples and their new welding technique creates a much more pressure-resistant disk: with a bursting pressure of 36 bar, it safely allows for a rated inner pressure of 5 bar.

- The reduced disk pitch increases the compactness of the exchanging unit,allowing a significantly increase heat transfer in the same footprint of the original RCR design.

- The better fluid-dynamic control of the generated turbulence allows for higher rotational speed of the exchanging surfaces, thus increasing the self-cleaning, anti-fouling action of the rotating exchanger.