Trumonytechs - Model ESS -Prismatic Battery Pack Heat Transfer Stamping Liquid Cooling Plate

Outline envelope dimensions: 1700mm×1200mm×35mm. Component: Stamping runners+ quick connector. Material: 3003 alumiunum alloy. Connection method: brazing. Heat flow density of single cell: 9233W/m³. Temperature difference between inlet and outlet liquid: 3?. Maximum battery cell temperature: 29?. When the heat exchange demand is high, we also use stamping + fin design.

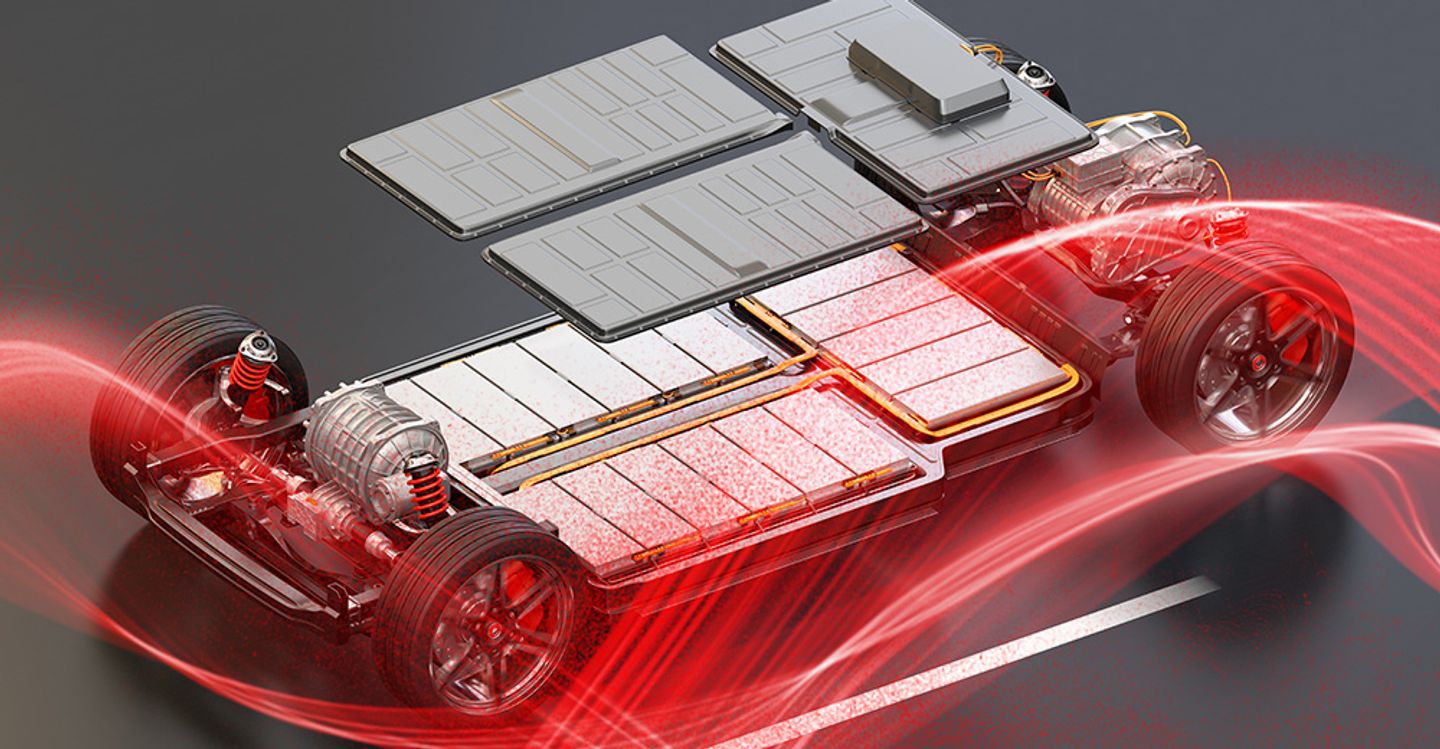

A great number of heat will produce when battery cell works, if it is not treated efficiently or timely, the cells will go in an extremely unstable state.

In this condition, liquid cooling is usually adopted to ensure the stable work performance of cells, thus the liquid cooling plates come out. As shown in the right picture, the heat of the cell will stepwisely transfer to the water cooling plates( solid conduction heat transfer from high temperature to low temperature )and then the coolant will run inside the channels to cool down the water cooling plate.

Trumonytechs offers professional manufacturing of water-cooled panels. Our professional R&D team has optimised the design for prismatic battery packs. The maximum temperature of the battery cell, the outlet liquid temperature and the prismatic battery pack temperature have significantly improved, as shown in the comparison chart below.

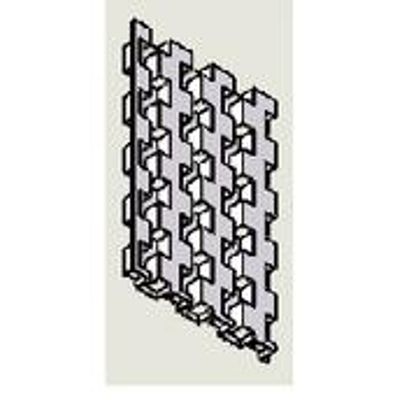

We can improve the heat transfer capacity of the water cooling plate by redesigning the flow channel structure to increase the flow rate and heat transfer area, so as to meet the higher heat transfer needs.