- Home

- Companies

- AMWEI Thermistor Sensor

- Products

- AMWEI - PTC Thermistor for Circuit ...

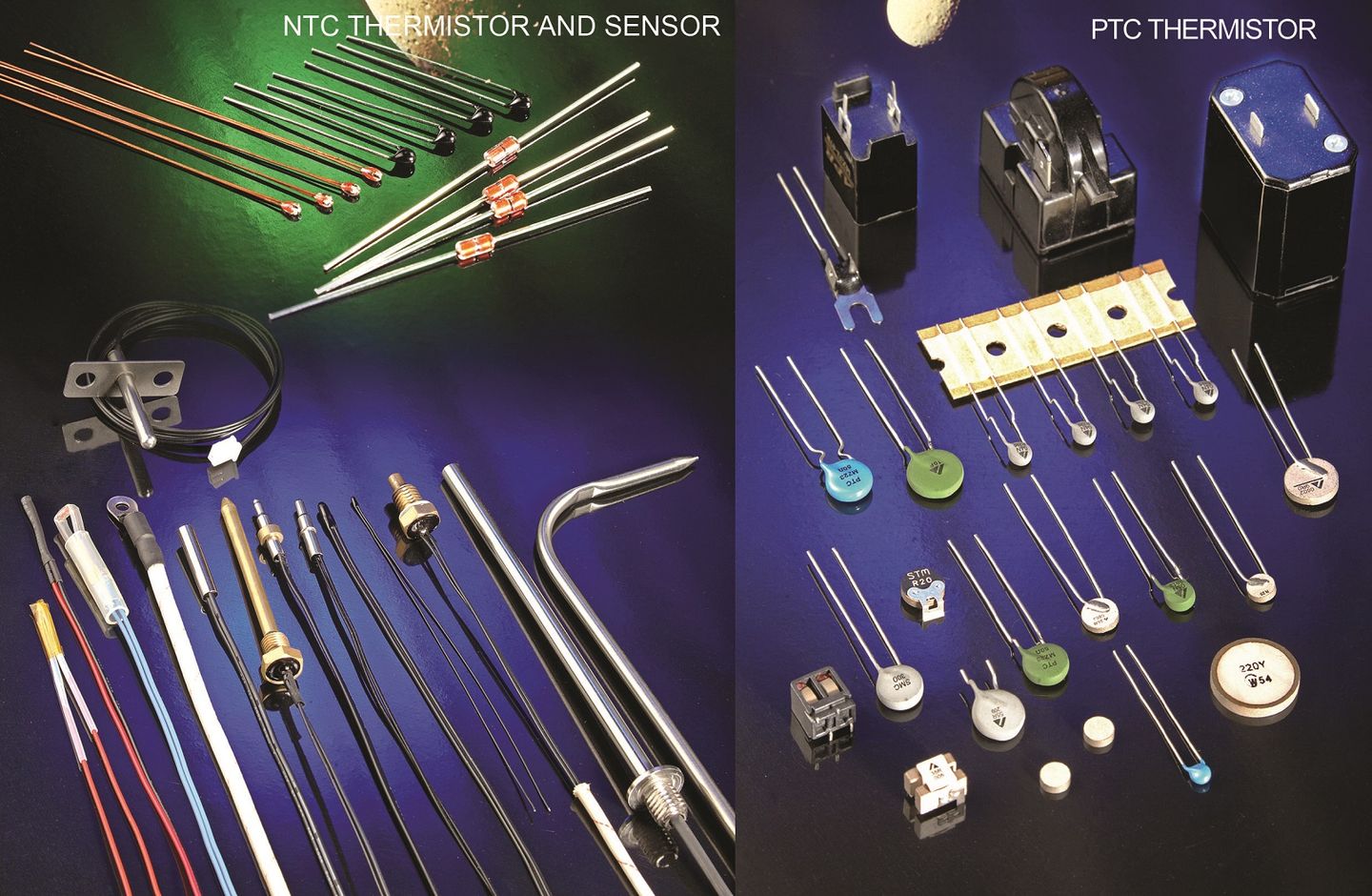

AMWEI - PTC Thermistor for Circuit Overload Over-current Protection

PTCthermistorsCircuit Protector, also calledPTCthermistorResettable fuse, are used instead of conventional fuses to protect load, such as motors, transformers, or electronic circuit, against overcurrent for circuit protection.PTCthermistorsprotector not only respond to inadmissibly high currents but also if a preset temperature limit is exceeded.PTCthermistorover-current protector limits the power dissipation of the whole circuit by increasing their resistance and thus reducing the current to a harmless residual value. In contrast to conventional fuses,PTCthermistorresettable fuses do not have to be replaced after elimination of the fault but resume their protective function immediately after a short cooling-down time.

PTC thermistors for Circuit Over-current Overload Protection Application

Positive Temperature CoefficientPTCthermistorapplies in the over-current overload and short circuit protection of transformers, battery charger, switches, switch power supply, adaptor, meter, instrumentation, apparatus, electronic coils, control panels, air conditioner, automotive electron, etc.

How PTC thermistor Resettable Fuse Protect Circuit against Overload Over-current Work? Operating Principle

PTCthermistorResettable Fuse Circuit Protection operating principle is as indicated in the following.

When a circuit is in the normal status, the current through PTCis lower than the rated current and PTCthermistorsprotector is in the normal state with small resistance value, which will not affect the normal operation of the protected circuit.

In case of some fault in the circuit and the current is greater than the rated current, the PTCthermistorprotector will become hot quickly and present a high resistance state, which sets the circuit relatively "off" to protect the circuit from damage.

After the fault is removed,PTCthermistorprotector will automatically restore its low resistance state and the circuit will resume normal operation.

Normally, whenPTCthermistoris used as an overcurrent protection component, it is preferred to select maximum operating current, maximum operating voltage and proper specifications. Furthermore such factors should be taken into consideration as the dimensions of the components, rated zero-power resistance, operating temperature range, etc.

Relation between operating temperature, operating current and non-operating current is as shown in Fig.2. Operating current is normally 2~3 times non-operating current, and both of the currents will be reduced as operating temperature increases.

Fig. 3 is Voltage-Current Curve and Load Curve in normal operating state. From point A to point B, the voltage onPTCthermistorprotector increases gradually, current throughPTCthermistorcurrent limiting device also increases linearly, it indicates thatPTCthermistorprotector resistance keeps almost unchanged, in low resistance state; From point B to F, the voltage increases gradually,PTCthermistorprotector resistance increases sharply due to heating, current throughPTCthermistorcurrent limiting device decreases rapidly, it indicates thatPTCthermistorcurrent limiting device in protection state. Normal load curve lower than point B,PTCthermistorover current protection device won`t enter into protection state.