- Home

- Companies

- Poly Fluoro Limited

- Products

- PTFE Tubing for High-Temperature and ...

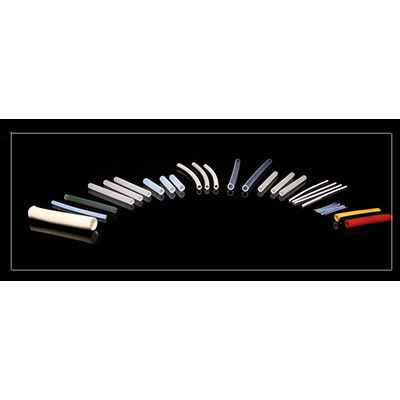

PTFE Tubing for High-Temperature and Electrical Insulation Applications

PTFE Tubing, also known as PolyTetraFluoroEthylene tubing, is renowned for its chemical inertness and non-toxicity, making it suitable for high-temperature resistance and facilitating fluid flow with minimal friction. Demonstrating resistance to temperatures up to 260°C and offering a breakdown voltage of 100Kv/mm, PTFE tubing is ideal for fluid transfer, cabling, and heat-exchanger systems. The tubing's versatility enables its use across medical, chemical, and automotive industries. FluoroTube, a product line from Poly Fluoro Ltd., delivers various grades and sizes, supporting applications like spaghetti tubing for medical and automotive uses, PTFE hoses for high-pressure demands, and PTFE sleeves for insulation, lubrication, and corrosion resistance. Each product variant is designed to meet specific needs, from thin-walled for tight spaces to heavy-walled for durable insulation.

PTFE Tubing (PolyTetraFluoroEthylene tubing) is a semi-transparent, chemically inert, and non-toxic material that features unmatched temperature resistance and a surface that facilitates the flow of fluids. PTFE tubes are used applications requiring resistance to high temperatures, corrosive chemicals, and high voltages.

As such, it finds use in fluid transfer applications, cabling, and heat-exchanger systems.

PTFE can be used in service temperatures of up to 260°C, making it a material of choice in high temperature applications. It also has a breakdown voltage of up to 100Kv/mm, making it ideal in electrical insulation

FluoroTube marks the entry of Poly Fluoro Ltd. into the PTFE (PolyTetraFluoroEthylene) tubing segment. We manufacture various grades and sizes of tubes, making FluoroTube ideal for medical, chemical, and automotive applications.

-

Spaghetti tubing – with a wall thickness of within 1.5mm and an outer diameter of less than 15mm, this tubing is used extensively in both medical and automotive applications.

-

PTFE hoses – these are heavy-wall thickness tubes and are used primarily in applications that need high-burst pressures or heavy insulation.

-

PTFE sleeves – these can be either extruded or compression-moulded. Their wall thickness is usually between 2-6mm, but the diameter could go up to as much as 300mm. Sleeves are used in a variety of applications that need insulation, lubrication, corrosion resistance, or load bearing.

- High chemical resistance : Suitable for carrying highly corrosive/reactive fluids

- Distinctly inert : Extensively useful in medical applications

- Withstands temperatures of up to 240°C : Effective in high-heat applications

- Superior dielectric strength : Insulating medium in cables and heavy electricals