- Home

- Companies

- Fote Machinery (FTM)

- Products

- Fote - Raymond Mill

Fote - Raymond Mill

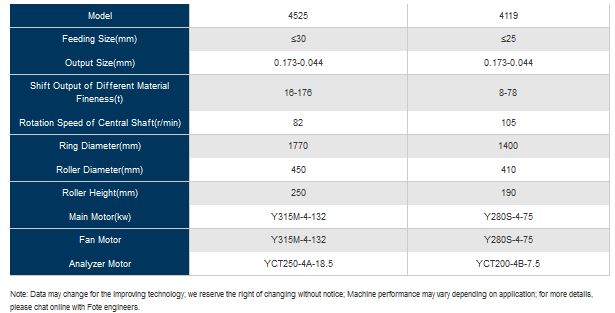

Applied Materials: clinker, coal, kaolin, bentonite. dolomite, garnet barite. slag, quartz, feldspar, calcium carbonate, etc. Exported to Over 200 Countries: India. Malawi. Iran. Russia. Liberia. Pakistan. Mexico. Vietnam. Zambia. Turkey. Ghana. South Africa and so on. Feed size: £25-£30mrn Capacity: 0.6-176 tons per shift

Introduction to Raymond Mill

Raymond mill is also called Raymond roller mill or Raymond grinding mill, which is one of the most widely used grinding equipment.

As one ancient grinding equipment, from its birth in 1906, Raymond mill has experienced generations of upgrading and the grinding technology has become more and more mature.

The new type of Raymond mill has a stronger grinding force with a protection device. Besides, the adjustment of the product fineness and the capacity can be finished during the Raymond mill operation.

In the beginning, Raymond grinding mill is only used as the coal grinding machine. While nowadays, the Raymond mill has been applied in all walks of life, especially in mines, chemical plants, pharmaceutical industry, refractory material factories, cement plants, etc.

Sometimes, Raymond mill can replace the ball mill, the latter of which has a higher cost. It realizes a highly efficient closed-circuit ultra-fine grinding, which ensures the final grinding effect.

Factors on Raymond Grinding Mill Capacity

There are many factors on Raymond mill, the direct ones of which are the material hardness, the material moisture, the finished product requirement, etc.

Material hardness: The harder the material is, the more difficult for the Raymond mill to grind, and the parts wearing is more severe.

Material moisture: If the material contents more water than about 6%, it is easier for the grinding chamber and the feeding system to be stuck. This will surely result in a reduction in the grinding capacity of Raymond mill.

Final product requirement: As the saying goes, soft fire makes sweet malt. When a smaller particle is required, the capacity of the Raymond roller mill is decreased accordingly.

Factors on the Grinding Effect of Raymond Roller Mill

Other factors on the grinding of Raymond mill are the shovel blades, grinding rings, and the number of grinding rollers. Fote has types of Raymond mills for sale with a different combination of main wearable parts:

- 3 rollers

- 4 rollers

- 5 rollers

- 6 rollers

- other customized types…

Here we go to get close to the Raymond mill working sites to see types of Raymond mills meeting different customers` requirements.

One of the most widely used grinding machines is Raymond mill. It has a lower cost than ball mill and smaller particle size than sand making machine.

Thanks to the modern technology and high-quality grinding solution, Fote Raymond roller mill is widely welcome. And it has been exported to countries and places around the world, such as India, Ghana, Indonesia, Pakistan, Vietnam, the United Arab Emirates, etc.

Fote 4R Raymond Roller Mill in India

Mr. Arnav in India has a coal plant. Coal needs to be ground into powder to improve the combustion efficiency. 3 years ago, he found Fote engineers on the Internet and provided requirements.

After several rounds of communication, Mr. Hashemi was presented with an efficient plan within the budget, including a 4R Raymond mill.

Coal grinding line in India

- Processed material Coal

- Capacity 50TPD

- Feed size 20mm

- Discharge size 325 mesh

Customer Feedback

This is the first time for us to contact Fote Machinery. Their professionalism and patience make us feel at ease. The coal powder produced by Fote Raymond mill meets the fineness requirements well. Our clients keep placing orders with us.

Raymond grinding mill can process over 200 kinds of non-flammable and non-explosive materials. The materials Mohs hardness is no higher than 9.3 and the humidity is less than 6% (a small floating can be handled).

If the material humidity is too high, natural drying is recommended for a small-capacity grinding line; while a small-type rotary dryer is recommended for a large-capacity grinding plant to dewater the materials.

Many kinds of materials can be processed by Raymond mill. They can be dolomite, kaolin, gangue, fly ash, bentonite, gypsum, limestone, coal, slag, mica, etc.

Generally speaking, the main applied areas of Raymond roller mill are as follows:

- In the coal industry and power plant, Raymond mill can be used to prepare pulverized coal and improve its utilization efficiency;

- In the chemical industry, refractory materials and other fields, Raymond mill can be used for production

- In the field of cement plant, dry mortar and building materials, Raymond roller mill can process limestone, etc. for the production of concrete and other building materials.

- In the metallurgical industry, Raymond mill can process slag, which is used for metal recovery to improve the service efficiency of metal ore.

Different types of Raymond grinding mills are needed in different materials processes.