- Home

- Companies

- Birk Wärmetechnische Anlagen GmbH

- Products

- Birk - Regenerative (thermal) ...

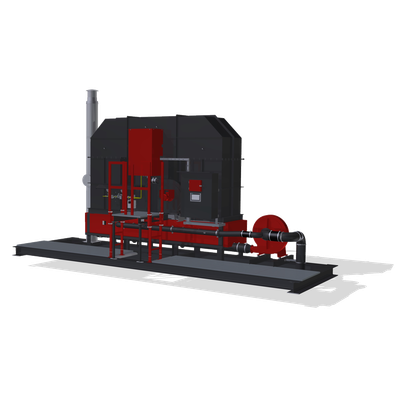

Birk - Regenerative (thermal) Post-combustion (RNV) System

Regenerative (thermal) afterburning is an exhaust air purification system using oxidation and integrated heat recovery for process exhaust air preheating. Depending on the process or clean gas requirements, working temperatures of 650...900 °C are achieved in the RNV combustion chamber with corresponding residence times. Like the TNV process, regenerative afterburning is an air-hygienically optimal process, since the exhaust air is completely converted into the harmless substances water (H2O) or carbon dioxide (CO2). Regenerative post-combustion plants offer a great deal of savings potential through integrated heat and energy recovery for the process air, whereby the energy costs to be used are minimised or, in autothermal processes, reduced to the use of electrical energy.

The "regenerative afterburning" process is particularly recommended for higher exhaust air volume flows and for processes in which no further generation of process heat (warm/hot water, thermal oil, steam) is required. Our regenerative post-combustion plants are specially adapted to each customer process and can also be subsequently adapted or extended to other processes. Our RNV plants are specially designed and adapted to the customer's installation site, whereby a cost-effective and effective exhaust air cleaning can be realised even in confined and minimal space conditions.

Possible and recommended areas of application for an RNV system:

- Chemical Processes

- coating processes

- painting processes

- Printing and packaging industry

- paper industry

- food industry

- surface treatment

- wood industry

- odor elimination

Extract from the range of services Regenerative afterburning plants

- Compact design

- System designs for indoor or outdoor installation

- Option: Version for installation in the food sector

- System designs for volume flows: 1,000 mn³/h to 50,000 mn³/h (higher volume flows on request)

- highest energy and heat recovery respectively autothermal processes

- Combination options for further heat recovery:

Process air/air heater

Warm/hot water production Thermal oil production and others

- Own efficient burner technology for the combustion plant in low NOx technology

- Integration of a RAD adsorber for concentration and minimization of the pollutant gas flow

- Advanced technology for minimal maintenance

- Portfolio of cost-effective "standard" RNV systems in specified sizes and applications