- Home

- Companies

- Eknis-Engineering, LLC

- Products

- Eknis-Engineering - Relay Protection & ...

Eknis-Engineering - Relay Protection & Automation Systems

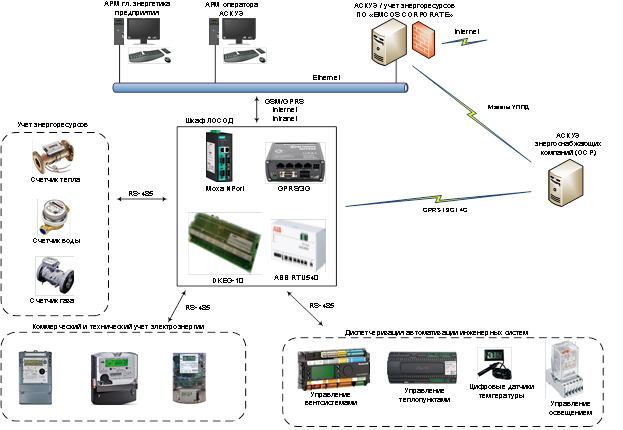

The company LLC "EKNIS-ENGINEERING" performs a full range of works on commissioning and modernization of Relay Protection and Automation and Emergency Control Automatics equipment in operation at power plants and substations with a voltage of 6-750 kV: pre-project inspection and design of project, equipment batching and supply of equipment, design and manufacture of Relay Protection and Automation and Emergency Control Automatics cabinets, installation and commissioning works, integration of microprocessor-based Relay Protection and Automation and Emergency Control Automatics equipment in Automatic process control systems and network control centers, service maintenance.

We use the equipment of leading world and domestic manufacturers to complete the Relay Protection and Automation and Emergency Control Automatics systems, depending on the technical requirements and wishes of the Customer:

- ABB

- Siemens

- General Electric

- Schneider Electric

- A «Kievpribor»

- R&D enterprice «Hartron-Inkor»

- CJSC «Energomashvin»

- LLC«RZA-Systems».

Advantages of the implementation of Relay Protection and Automation projects by LLC "EKNIS-ENGINEERING":

- development standart design solutions for Customer;

- introduction of relay protection and automation systems to reduce operating costs without reliability weakness;

- automation of switching operations in relay protection and automation equipment;

- ensuring compliance with the requirements of modern information security protocols;

- use of relay protection cabinets that have passed factory inspection in accordance with the design documentation;

- use of modern testing facilities during commissioning (OMICRON, Retom);

- certified specialists who have undergone comprehensive training from manufacturers of microprocessor relay protection equipment.

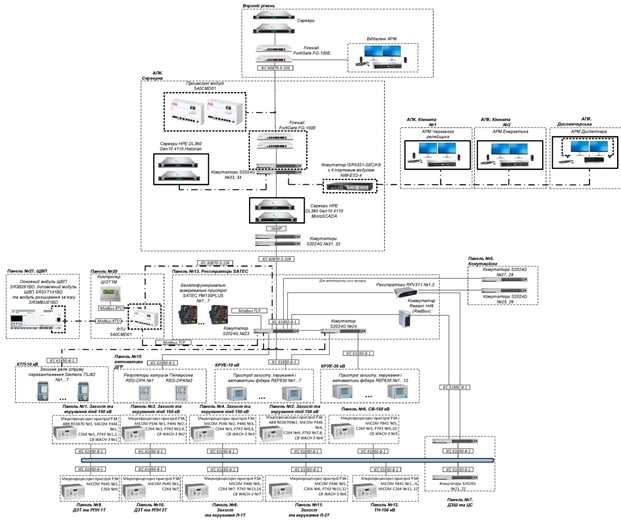

One of the first Ukrainian digital substation "Prymorska WPP-2" was put into operation by specialists of LLC "EKNIS-ENGINEERING" in 2019

The technology of “digital substation” - the basis of “smart grids” is the exchange of data between field-level equipment with fully digital Relay Protection and Automation and Emergency Control Automatics equipment, using a single standard IEC 61850 protocol. In contrast to the conventional substation, which uses the exchange of electric analog/digital signals using a large amount of cable-conductor products and has high installation costs, the digital SS combines the mode of «digital» equipment interaction with high reliability and availability of the system.

The basis of digital substation building is complex integration of high-tech relay protection equipment and modern primary equipment with supporting IEC 61850.

The key element of the digital substation is the presence of two independent, hardware-separated data transmission buses - the process bus (Process Bus) and the station bus (Station Bus).

The IEC 61850 process bus makes it possible to replace point-to-point copper connections between various devices (IEDs, measuring transformers, monitoring systems, etc.) and switchgear equipment with a secure, standardized optical telecommunication network, with which it is possible to transmit data from the source of this data to all devices subscribed to them with high speed, reliability, discreteness and accura?y. Due to the process bus, information on measurements and conditions of equipment can be distributed throughout the substation in real time without the need for complex cable communications.

The bus of the IEC 61850 station is based on the implementation of horizontal data exchange (GOOSE and MMS messages) with the help of which it is possible to organise the exchange of data between protection devices (mutual interlocks, starts and operation of protections, etc.), as well as organise data transfer to substation control systems.

Building a digital substation makes it possible to significantly reduce the number of cable connections and to speed up the testing and commissioning procedures, to maintain the equipment and to analyse in detail the non-standart or accidental events that have occurred on the site. Due to digital technologies, it is possible to continuously monitor and control the critical functions of switchgears of all voltage types, transformers and other substation equipment, which makes possible precautionary maintenance on the condition of this equipment.

The implementation of digital substations allows energy companies to increase productivity, reduce the area occupied by equipment, increase functionality, increase reliability and provide greater security for service personnel.