- Home

- Companies

- KONČAR - Electrical Engineering ...

- Products

- KONCAR - Model ST&P - Shaft Torque and ...

KONCAR - Model ST&P -Shaft Torque and Power Monitoring System

Torque, speed and power are the defining mechanical parameters associated with functional performance of rotating machines (machine efficiency determination). ST&P system enables insight into this important machine parameters by on line measurement of shaft twist angle. The system uses two precise optical fork sensors for twist angle measurement. Besides on-line torque measurement, ST&P system enables measurement of power and rotating speed.

Fork sensors:

- No contact interference with the shaft

- Optical sensor with digital output

- Rugged construction

- Simple installation (code disk is not required)

Processing unit:

- Real time processing

- Analog outputs and digital outputs (alarms)

- Communication outputs

- Data base (trends, waveforms, alarms …)

- Local/remote HMI

Architecture:

- Data acquisition unit with the real time controller and local visualization

Inputs:

- Two digital inputs (PNP or NPN)

- Resolution time stamp: 1ns

- Analog outputs (on request)

- Current outputs 4 - 20 mA, voltage outputs 0 - 10 V

- Number of outputs : 2 to 4

Digital/relay outputs:

- Number of outputs: 2 to 8

- Continuous current: 6 A

- Maximum switching power: 1500 VA

- Maximum switching voltage: 250 VAC/DC

- Maximum switching frequency: 0,1 Hz

- Rated isolation voltage: 300 V overload (category III) by EN 50178

- Surge withstand: 4 kV (1,25/50 μs), by IEC 5017

Communication:

- Ethernet 10/100

- Supported protocols: Modbus TCP slave, FTP server, IEC 60870-104, HTTP server (other on request)

Power supply:

- DC: 80 V to 370 V

- AC: 85 to 264 V , frequency 47 to 63 Hz

- Maximum allowed power supply interruption: 100 ms for 230 VAC/ 20 ms for 115 VAC

- Test voltage: 3 kV (2 kV against ground)

Temperature range:

- Operational temperature range: -20°C to +70°C

- -0°C to +55°C (for EMCM variant with touch screen)

- Storage temperature range: -40° to +85°C

Dimensions:

- 19” installation – WHD: 482,5x177,5x250 (typical dimensions)

- Cabinet IP 54 (IP 66 on request) – WHD: 300x300x200

Data visualization:

- Web browser for remote access and local client application through touch screen

Data logging:

- Database for long-term data, alarm and events storage

Standards compliance:

- EMC immunity/emission (EN 61000-6-2/EN 61000-6-4)

- Vibration/shock resistance (EN 60068-2-6/EN 60068-2-27/29)

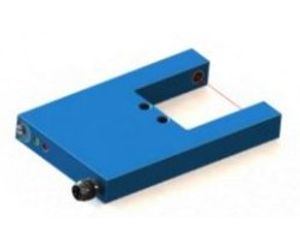

Fork optical sensor:

- Integrated electronics

- High sensitivity

- Switching frequency 500 kHz

- Infrared light beam

- Switching state indicator : yellow/green led

- Scratch resistant optics

- Aluminum housing

- Current consumption: 80 mA

- Enclosure rate: IP 67

- Operating temperature range: -20°C to +70°C

- Dirt accumulation indicator: red led

- Size: 80x50x10

- Analog output: YES (voltage)

- Digital output: YES (NPN/PNP)

Complete documentation required for system installation, maintenance and usage of the ST&P system. Usual scope of the documentation:

- Mechanical documentation (book I)

- Electrical documentation (book II)

- User instructions (book III)

- Certificates, test reports… (book IV)

Users can get insight into measuring data through local touch display (local HMI) and through web server (web application). Local visualization enables insight into real-time data, trends and setup. All screens can be modified according to the Customer’s requests which includes native language.

The ST&P system is equipped with a multiuser web server which enables remote access and overview of all system data through standard web browser. This web server provides access to the ST&P system from any desktop or a laptop computer (with Windows or iOS operating system), tablet (with iOS, Android OS…) or smartphone (with iOS, Android OS…). System access is provided without the need for installation of any additional software, using a standard web browser (Google Chrome, Internet Explorer, Mozilla Firefox, Safari …). Web server enables insight into real-time data, trends, waveforms and alarms for measurement values increase as well as for fault detection.