- Home

- Companies

- Beston Group Co., Ltd.

- Products

- Beston - Model BLJ - Small Pyrolysis ...

Beston - Model BLJ -Small Pyrolysis Plant

Small pyrolysis plant is suitable for converting a small amount of tyre waste to oil. The harm of non-degradable waste is known to all. Beston machines have played an important part to improve the utilization of waste and reduce the pollution. Nowadays. Its easy installment and small occupied area are favored by customers.

Raw Materials for Beston Small Scale Pyrolysis Plant

Beston small pyrolysis equipment can handle a wide range of raw materials. Please refer to the following types. If you have different materials to process, please consult us.

Note: PVC and PET can’t be processed in the pyrolysis furnace.

- Car/truck/bus/van/SUV tyres

- Bicycle/motorcycle Tyres/electric motor

- Aircraft tyres

- Agricultural vehicle tyres: tractor tyres, harvester tyres, etc

- Engineering machinery tyres: excavator tires, transport machinery tires, etc.

- And other tires

- PE (Polyethylene)

- PP (Polypropylene)

- PS (Polystyrene)

- ABS (Acrylonitrile Butadiene Styrene)

- PA (Polyamide), etc.

- Other kinds of plastic waste.

- Transportation industry: rubber holsters, rubber conveyor belts, etc.

- Industrial mining industry: gaskets, rubber rollers, rubber sheets, etc.

- Civil construction industry: sound insulation floors, rubber carpets, etc.

- Electrical communication industry: wires, cables, etc.

- Life: Soles, raincoats, children’s toys, sponge seat cushions, etc.

- Drilling cuttings contained oil

- Oil sludge

- Ship bottom sludge contained oil

- Tank sludge contained oil

- Oil soil

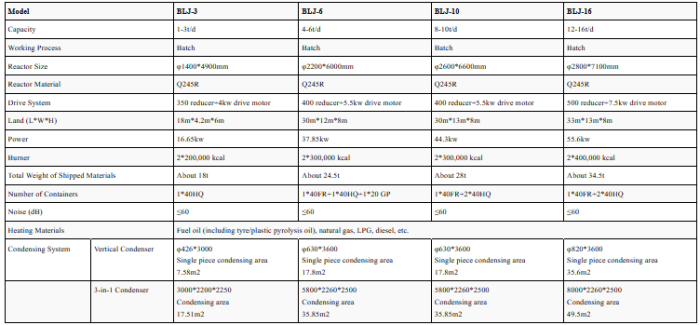

For small type, Beston provides four models, including BLJ-3, BLJ-6, BLJ-10 and BLJ-16. See their parameters.The following table shows data of standard small pyrolysis line for your reference.

Note: for different materials, there will be a difference in capacity. Contact us to know the detailed capacity.

The quality of the small scale pyrolysis plant greatly influences the service life. When investors choose a suitable waste pyrolysis machine, efficiency and safety are the most common consideration. Beston provides several models with different capacities. And all of them have good design and good quality. View the following features:

Beston equipment adopts the industry’s advanced technology – meteorological catalytic plastic pyrolysis technology. This technology can solve the technical problem of wax oil clogging the pipeline. This will help ensure the continuous and stable operation of the equipment. At the same time, the yield of pyrolysis oil is also improved.

The Internet of Things system has intelligent data remote transmission and control system. The mobile terminal of the device realizes timely online monitoring of the Internet of Things, which is convenient for customers to control the overall operation. This technology reflects the advanced technology of Beston equipment.

If the customer chooses Beston, we can provide the following value-added services for the customer according to the customer’s site, including layout drawing, installation drawing, PID drawing, 3D drawing, free system software upgrade service, and so on. These services will help customers reduce additional fee.

Beston has been continuously increasing product research and development technology. We have developed the BLL-30 fully continuous pyrolysis equipment. This equipment incorporates technical solutions for alleviating coking during oil sludge pyrolysis. This ensures stable and continuous operation of the equipment.