Currently SST is able to make prototype and demonstration systems in preparation for commercial manufacturing partnerships. Target cost for this Dish-CPV product is under $2/W in high-volume manufacturing, using CPV “multi-junction” PV cell technology that is on a pathway for increasingly high efficiency. Expected CPV cell improvements over time will increase the module rating from initially 1 kW (including all system losses), to about 1.7 kW per module. These efficiency gains help to reduce the effective cost of the collector system. Two-axis tracking is used which provides for about 20-30% higher energy output than a fixed-PV system of the same rating, assuming sunny conditions, and higher annual output than solar trough or tower systems.

- Home

- Companies

- Southwest Solar Technology Llc

- Products

- SST - CPV Dish for Concentrated Solar ...

SST - CPV Dish for Concentrated Solar Energy Collection

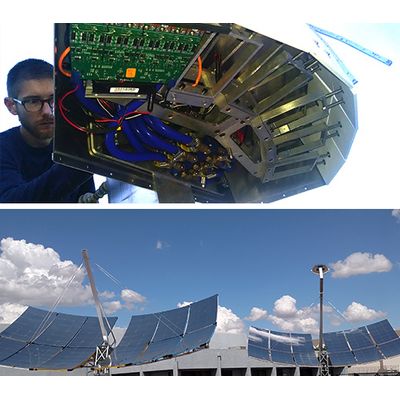

The SST CPV Dish from Southwest Solar Technology is a sophisticated concentrated photovoltaic system designed to optimize solar energy collection in harsh environmental conditions, such as high temperatures and desert regions. Unlike traditional CPV designs that employ lenses, this dish utilizes a 'dense array' CPV module as a building block, rated at a nominal 1 kW. It features a water-cooling system similar to automobile engine cooling, enabling dry-air cooling that conserves water resources while effectively managing thermal output for solar cells operating under intense sunlight exposure, exceeding 1000 suns. The system incorporates high-efficiency CPV 'multi-junction' PV cell technology, with a target cost of under $2 per watt in mass production, and upgrades are anticipated to elevate its power rating to approximately 1.7 kW. A two-axis tracking mechanism ensures optimal energy collection, increasing output by 20-30% compared to similar fixed systems, while offering higher annual productivity compared to trough or tower solar systems.The SST Concentrating PV (CPV) solar module system is a modular liquid-cooled CPV design that is integrated with the optics of the SST solar dish. In some cases the CPV module could also be used with tower/heliostat collectors. 12 CPV modules are packaged into the Receiver that is used with the SST dish. As this technology is still in development, the initial target rating is 10 kW for pre-production dish units, with 15 kW as the commercial target rating.

Unlike the more common CPV designs that use lenses, the SST CPV design is based on a nominal 1 kW “dense array” building block CPV module. The CPV module uses water cooling, circulated in a closed loop to a radiator like a car engine cooling system, and so it is dry-air cooled and does not consume water. This liquid cooling method provides better thermal management of CPV solar cells operating under very high concentration – over 1000 suns – and for better solar production in high temperature and harsh desert regions.

But heat and dust can cause durability problems in the typical “lens-box” CPV designs, where dust can leak past seals and accumulate internally where it cannot be cleaned. Heat and condensation in lens systems can also degrade the optical performance of lenses, which typically are a combination of glass and silicone.

NEW IMPLEMENTATION OF CPV

The SST CPV design reduces these problems by using a mirror to concentrate the light externally to a more compact Receiver with 12 CPV modules. Each CPV module accepts about 200-400-times concentrated sunlight from the dish mirror collector, and so it is about 200 times more compact than “lens-box” CPV modules. It can be better sealed and protected against dust, water and heat. All of the optical surfaces are glass or quartz for durability. The SST mirror panels use thin-glass mirrors, with proven performance and durability. In the future, non-glass reflectors can be considered and used with the SST mirror panel, when they provide advantages.

Because of the high efficiency of CPV cells, currently exceeding 40%, less land area is required per megawatt. Dishes are arranged with about 75% of the land as “open space” between units to minimize shadow losses. At a 12 kW rating this provides over 500 kW per hectare (10,000 m2), or 5 acres per megawatt, assuming nominal spacing between dishes.

The target power rating per dish will increase over time. With pre-production fabrication methods and current CPV cell efficiency (42%), the power output is expected to be 10 to 12 kW. As the manufacturing is brought to full commercial status the power output is expected to reach 15 kW. Future CPV cell efficiency has potential to exceed 50%. With improvements in CPV cells the Dish-CPV system is expected to increase to 16 kW in the near term, with up to 20 kW possible over time. This long term efficiency goal could provide nearly a MW per hectare, or less than 3 acres per MW.

While most CPV designs use lenses, there have been few Dish CPV designs. The SST CPV approach was developed to avoid some of the problems of lens-CPV designs. In addition, the SST Dish system offers heat energy, which other CPV does not provide.