- Home

- Companies

- Surface Combustion, Inc.

- Products

- Surface Combustion Allcase - Batch ...

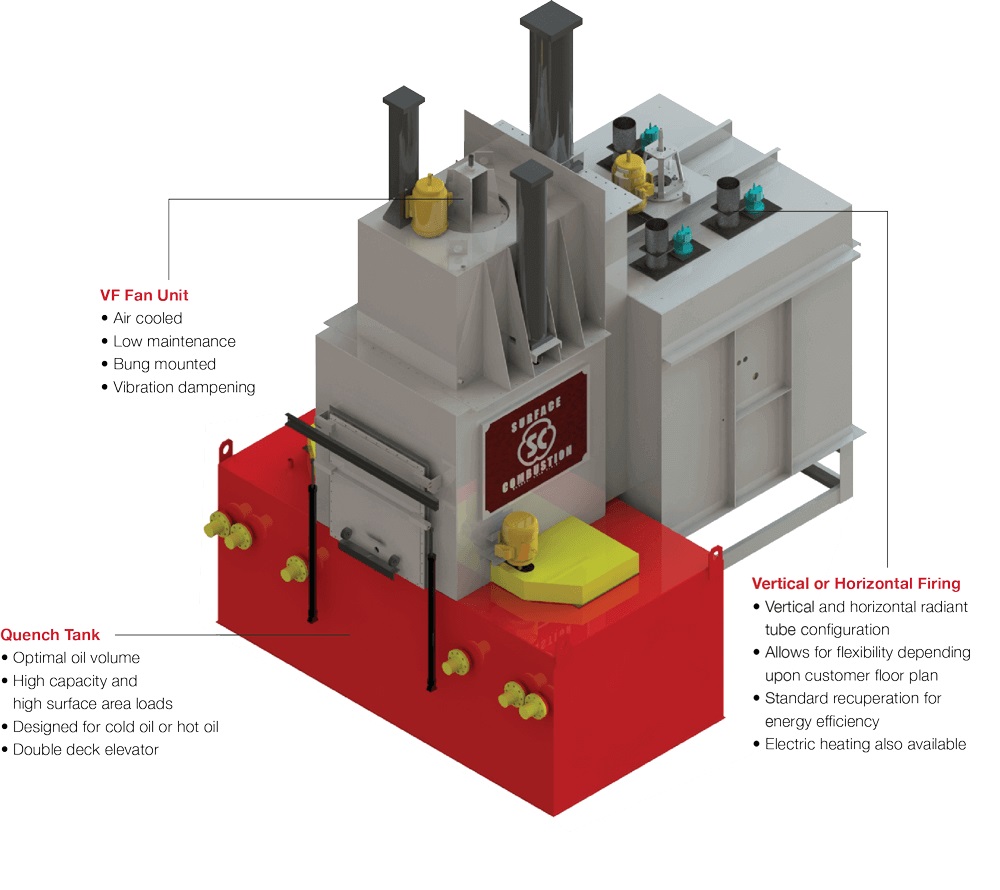

Surface Combustion Allcase - Batch Integral Quench Furnace

Allcase® Batch Integral Quench Furnace: Industry-Leading Thermal Processing Solutions. Over 3,000 Allcase® Furnaces Worldwide. When you look to purchase anything in life, you always feel more comfortable when you go to the experts. As an industrial furnace manufacturer, Surface Combustion has more installed base and sells far more new Allcase® Batch Integral Quench Furnaces than any competitor in the US. Beginning in the early 1950’s, we introduced this innovative and versatile style of batch furnace to industry.

Manufacturing engineers and plant managers select the Allcase® batch integral quench furnace for compelling operational advantages:

Process Flexibility

A single furnace can perform multiple thermal processes, adapting to changing production requirements without additional capital investment.

Proven Reliability

Surface Combustion’s robust construction and standardized designs minimize downtime and maintenance requirements.

Metallurgical Consistency

Precise atmosphere and temperature control ensure repeatable case depths, hardness profiles, and microstructures.

Energy Efficiency

Standard recuperation systems and optional advanced controls minimize fuel consumption and operating costs.

Lifetime Support

Surface Combustion’s aftermarket parts inventory and service team ensure decades of productive operation.

From initial process development through equipment commissioning and lifetime support, Surface Combustion provides the expertise to maximize your heat treatment capabilities.

The Allcase® excels in diverse thermal processing applications:

- Annealing

- Carbonitriding

- Carbon Restoration

- Carburizing

- Marquenching

- Neutral Hardening

- Normalizing

- Spheroidizing

- Stress Relieving

- Triniding™/ Ferritic Nitrocarburizing

Available in six standard work sizes and four configurations, the Allcase® can be fully automated with companion equipment for complete processing.

Our handling systems include:

Extended Reach™ System, an operator-initiated load movement through vestibule, heating chamber, and quench tank via charge car or table.

Push/Push operation features automatic rear handling and quenching with the fastest quench transfer time—ideal for thin parts and compatible with ShuttleTrac™ automation.

System #1™ combines operator-initiated vestibule handling with automatic rear handler and elevator systems.

Surface’s Allcase® systems incorporate efficient gas heating with vertical “U” tubes or horizontal Trident® tubes, or electric heating with patented Proelectric® elements. The optimized quench system and double deck elevator enhance productivity by allowing simultaneous quenching and charging.

Process Optimization Utilizing Tailored Heat Treating Solutions

Customization options include automation, extended reach operation, top cool chambers, hot oil quenching, and multiple atmosphere options.

The Allcase® delivers proven flexible processing of diverse components, rugged construction for heavy loads, consistent long-term performance, and efficient operation with recuperated combustion systems.

Ideal For:

- Castings

- Forgings

- Gears

- Hand tools

- Shafts

- Machined components where quality and process flexibility are essential.