- Home

- Companies

- Pyro Green-Gas (formerly known as ...

- Products

- AirScience - Model TSA - Thermal Swing ...

AirScience - Model TSA -Thermal Swing Adsorption Process System

This is the most effective siloxanes and VOCs removal system. It combines the removal efficiency of the activated carbon technology with the low operating cost of the VSA system. TSA can treat high loads of siloxanes and VOCs and its thermal desorption process assures that the adsorbent will have an extended usable life.

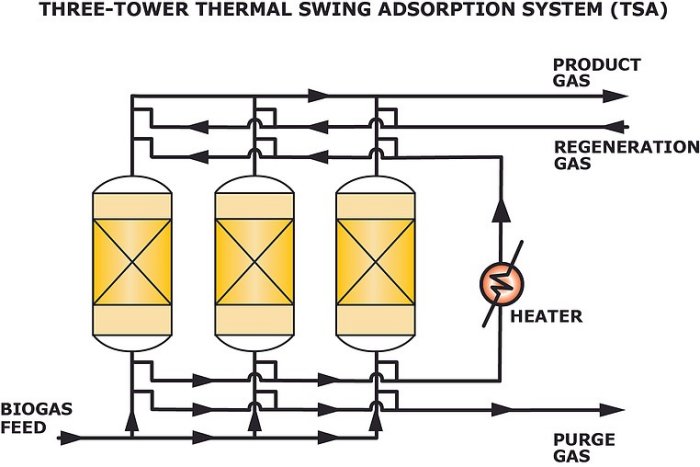

In a TSA system the gas passes through the adsorbent where the contaminants, siloxanes and VOCs are adsorbed. During that time the two other towers are off line, one being heated, the other one cooled. As one tower gets close to saturation, it is taken off-line and switched to regeneration mode while the tower who finished regeneration/cooling mode is brought back on line.

Regeneration gas (usually vent gas from the CO2 removal unit) is first passed through the tower which finished its regeneration/heating cycle to cool the media bed back to the operation temperature, the gas exiting that tower is further heated in an electric heater then passed in a counter-current mode through the quasi saturated tower, slowly heating the adsorbent bed, and desorbing siloxanes and VOCs. The vent gas is then directed to a thermal oxidizer to be incinerated. Once the complete adsorbent bed has been desorbed the hot bed goes through the cooling stage. At that time, the third tower which has completed its cooling stage is brought back on line and the adsorption, desorption, cooling sequence continues providing a continuous VOCs and siloxanes removal from the biogas.

In cases where regeneration gas is not available a three tower TSA arrangement is provided where one tower acts as a regeneration gas generator using a split stream of the raw feed gas. In this case the discharge of VOCs and siloxanes is in the form of a condensed liquid rather than a gas. The adsorption, desorption, cooling sequence is the same as for the TSA with regeneration gas.

In cases of small gas flow is low and low levels of VOCs and siloxanes a two tower TSA system can be used, however as flow and concentration of contaminants becomes higher, the size of a two tower system becomes too large to be practical and a three tower system is implemented.