Vobis - Thermal Vapor Recompression (TVR)

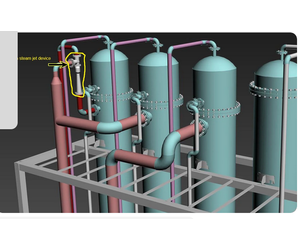

Thermal Vapor Recompression (TVR) or Thermal Vapor Compression can be implemented with our single or multiple effect Falling Film Evaporator Systems or our Forced Circulation Evaporator Systems for energy conservation. Incorporating Thermal Vapor Recompression requires steam for the operation of a thermal vapor compressor. The compression of steam results in heat recovery which is utilized in heating the system. This can often offset the need for an additional evaporator stage.

- Thermal Vapor Recompression is integrated in an evaporator system when the reduction of energy consumption is a primary goal.

- Much like Mechanical Vapor Recompression (MVR), Thermal Vapor Recompression enables low temperature operation under vacuum operating conditions and protects heat sensitive materials.

- The steam requirements for an evaporator system with Thermal Recompression is much less than a system without it, often eliminating the need for another effect, and thus increasing the system’s cost effectiveness.

- Allen Bradley or Siemens PLC control systems are typically implemented to accurately and reproducibly control our mechanical vapor recompression evaporation systems.

- Skid mounting or Modularization allows easy installation as well as ready access to all piping, pumps, control elements, and process vessels.

In Vobis Evaporation systems utilizing Thermal Vapor Recompression, high pressure steam is used to compress vapor from the evaporator which is then condensed in the heat exchanger. Primarily applied to a single effect evaporator or in the first effect of a double or triple effect system.