Promethean Energy

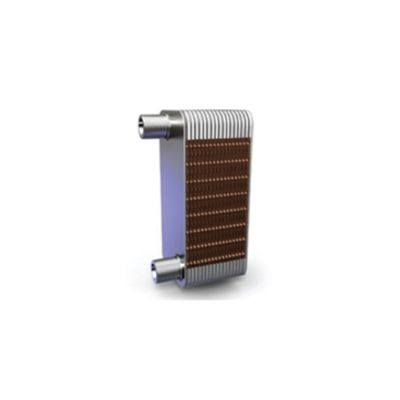

Model Flow Therm -Waste Heat Gases

Waste heat recovery from hot gases. Hot water/LP steam recovered at 100°C. Reduce hot air temperature before discharging to environment. Recover energy from streams of hot gases including boiler exhaust, furnace dryers, and air streams to generate useful energy in the form of hot air or hot water to be used in the process. Huge amount of energy is rejected as waste heat gases. Energy can be extracted from waste heat which in return will help in energy savings and cut down the energy consumption of the industry.

Most popular related searches

waste heat

heat recovery system

waste heat recovery

heat recovery

recovered energy

waste heat energy

boiler exhaust

energy consumption

energy saving

waste-to-energy

- Automotives

- Dairy & Ice-cream

- Textiles

- Food & Beverages

- Hotels & Hospitality

- Chemical

Hot water at almost no cost

Recovers waste energy to generate zero cost hot water with payback period of 12-18 months.

Clean Technology

Reduces the usage of boiler for hot water which directly adds up to reduction in the CO2 emissions and helps build a greener plant.

Very Compact, Modular & Minimal maintenance

Less than 1sq.m cross section is required for 5000 cfm of air flow rate.

Lower cost of gas treatment

Removes overall heat of the exhaust gases leading to minimizing the cost of gas treatment and helps to generate hot water at less cost.

Online data monitoring

Continuous data acquisition and monitoring of heat recovery system to ensure transparency in savings.