- Home

- Companies

- Martin GmbH für Umwelt- und ...

- Products

- Martin - Model SYNCOM - Waste-to-Energy ...

Martin - Model SYNCOM -Waste-to-Energy Plant

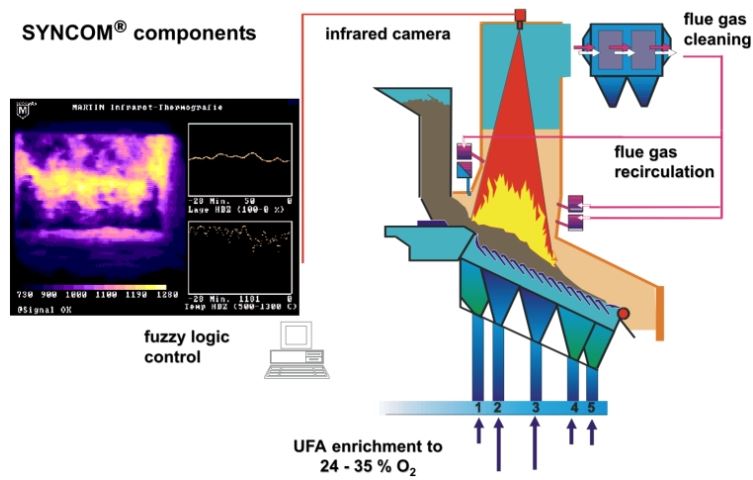

The limit values for emissions applicable to waste-to-energy plants are more stringent than those applying to any other type of industrial plant. Irrespective of this, the trend to further minimize pollutant emissions is continuing. At MARTIN GmbH, this led to the development of the SYNCOM process, which consists of the following components:

- grate-based system using the reverse-acting grate

- oxygen enrichment of primary air

- combustion control system using infrared (IR) thermography

- secondary air system with four nozzle rows – 4-row stitching

- flue gas recirculation

Flue gas recirculation and, above all, oxygen enrichment of the primary air substantially reduce the flue gas flow. This results in cost savings as smaller components can be used in the steam boiler and flue gas cleaning system. Also, pollution burdens at the stack are significantly reduced.

The complex combustion control system, which makes use of IR thermography, and the adjusted secondary air injection system ensure that the combustion process is optimized. Organic components are destroyed in a more efficient manner. Fuel bed temperatures are significantly higher than those in conventional plants and lead to partial sintering of the bottom ash. Bottom ash burnout and heavy metal leaching are significantly improved as a result.

Since 2004, a SYNCOM-equipped plant has been operating successfully on a continuous basis in Arnoldstein, Austria. In the Japanese city of Sendai, a further plant using the SYNCOM process started operating in 2005.

Highlights of the SYNCOM process:

- more intense, more uniform combustion

- significantly reduced CO content in the flue gas

- temperature in the fuel bed in the main combustion zone approx. 100 °C higher

- partial sintering of the bottom ash

- improved burnout

- less leaching of heavy metals

- flue gas flow reduced by approx. 35 %

- higher boiler efficiency

- reduced pollutant burden at stack

- reduced fly ash flow