- Home

- Companies

- Mechanical Solutions Inc. Testing & ...

- Software

- MSI - Version Pro - Wind Turbine

MSI - Version Pro -Wind Turbine

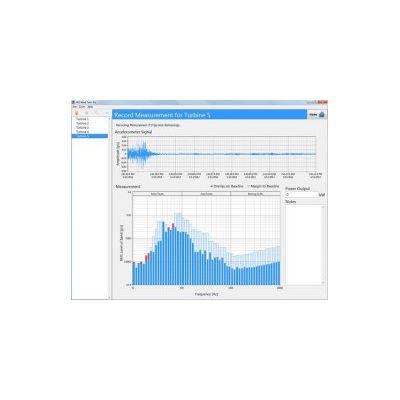

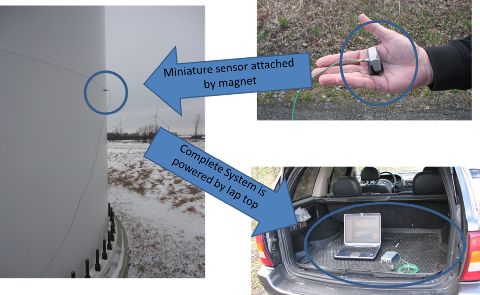

MSI Wind Turbine Pro is a portable, non-intrusive predictive health monitoring system for the wind power industry. The system includes software and USB-powered data acquisition hardware, and works with any standard Microsoft Windows laptop. Temporarily attach the magnetically-mounted accelerometer to the tower base, record a snapshot of data, and instantaneously view analysis results. No nacelle access needed. The system can be easily carried from turbine to turbine for periodic measurement and comparison.

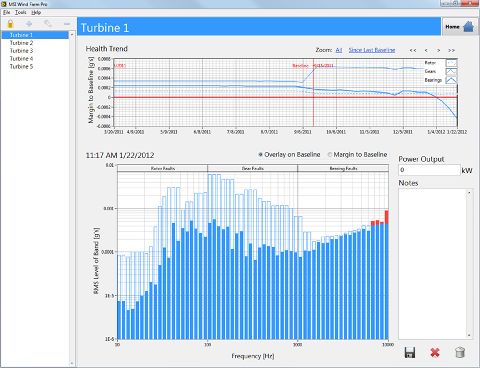

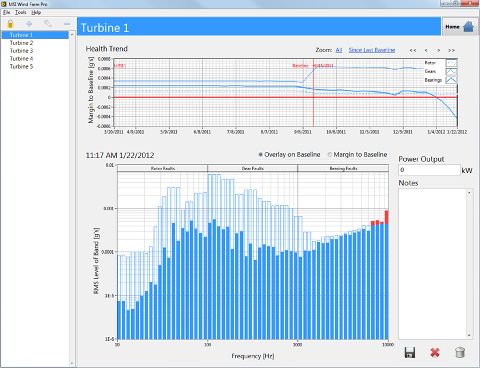

MSI Wind Turbine Pro is a handy tool for quick and easy overall assessment of wind turbine operating condition. Periodic measurement provides valuable information for Condition-Based Maintenance. In this example, the red bars show where the measurement has exceeded a preceding baseline measurement, and in this frequency range, suggests a potential rotor/shaft problem, with a recommendation to check for imbalance or misalignment, for example as might occur in gearboxes and generators.

The data acquisition hardware is an off-the-shelf USB chassis (such as provided by the National Instruments or by Sequoia, SPA) outfitted with a multi-channel accelerometer module. A magnetically-mounted minimum single-axis piezoelectric accelerometer is used to measure turbine vibration at the tower base. MSI can ship a turnkey system or just the software, with you supplying the data acquisition hardware, sensor, and laptop.

MSI Wind Turbine Pro uses an industry-standard accelerometer (left). It connects to an off-the-shelf USB chassis (such as provided by the National Instruments or by Sequoia, SPA) via a standard low noise coaxial cable (center). Not shown: A standard Windows based laptop and a magnetic base to attach the accelerometer to the wind turbine base.

The software provides the environment to:

- Enter turbine information and configure each tower at your site

- Record a baseline signature of each turbine

- Record data snapshots on each turbine and compare analyzed results to the baseline

- Trend component health, broken down by rotors/shafts, gears, and bearings

- Perform advanced bearing diagnostics to pinpoint faults to the specific bearing and component (inner race, outer race, cage, or rolling element)

- Collect up to four channels of data from a variety of sensor types in a “tape recorder” mode, with the data to be analyzed externally (e.g. with MATLAB, Excel, LabVIEW, etc.)

The system uses a constant percentage bandwidth (CPB) spectrum to quantify the turbine vibration in the frequency domain. Also known as a fractional octave spectrum, the CPB spectrum sorts harmonic signal components into ever-wider frequency bins, giving the system independence of operating condition, including speed. Trending the overall magnitude of the vibration of each bin allows the user to track the evolution of component health, considered seperately in terms of rotors/shafts, gears, and bearings.

The MSI Wind Turbine Pro software provides a convenient interface to watch the evolution of measurements over time by dragging a cursor left or right along a time axis. The margin to baseline for each of the three fault types (rotor, gear, and bearing) is trended along the same time axis at the top of the window.

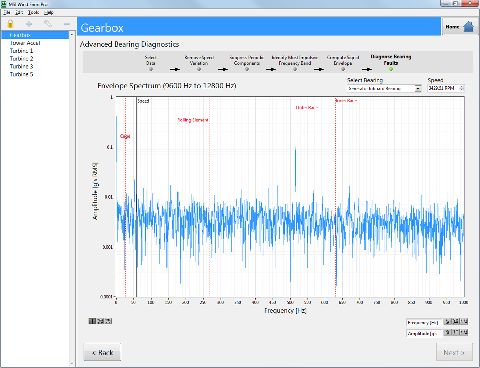

When there is a suspected bearing fault, the Advanced Bearing Diagnostics feature allows the user to pinpoint the component within a specific bearing that may be damaged:

- If bearing geometry information was entered by the user, the software places cursors that align with specific fault frequencies (inner race, outer race, cage, and rolling element) on an envelope spectrum

- A cursor aligning with a significant spectral peak provides additional identification of deterioration of the particular bearing component corresponding to that cursor.

The red bars in this frequency range indicate a potential bearing problem -- the operator may use the Advanced Bearing Diagnostic feature to pinpoint the location of the potential fault to the exact bearing and component. The operator may consider use of temperature, oil particulate counters, and other sensor information for confirmation.

This method uses phase demodulation to remove speed variations in the vibration signal, spectral whitening to attenuate synchronous vibration sources and accentuate impulsive vibration sources, such as those from bearing faults, followed by Kurtogram analysis to identify the most impulsive frequency region to use in computing the signal envelope.

When bearing geometry is known, the Advanced Bearing Diagnostics feature of MSI Wind Turbine Pro can help identify the exact bearing and component (inner race, outer race, cage, or rolling element) which contains a fault.